I. Introduction

For anyone who has ever ventured into the domain of industrial construction or architectural design, the term “Bar Grating Stair Treads” might ring a bell. But for those unfamiliar with the concept, bar grating stair treads are essentially a series of metal bars joined together to form a robust, versatile structure.

These structures serve as stair treads, capable of bearing substantial weight while simultaneously offering a safe, non-slip walking surface. Given their numerous advantages, Bar Grating Stair Treads have become a cornerstone in industrial settings.

Are you ready to dive into the world of stair treads? Read on this thorough guide for more information!

II. Understanding Bar Grating Stair Treads

Bar grating stair treads are an essential component in industrial environments, providing safe, reliable walkways. The quality and functionality of these treads significantly depend on their material and pattern selection.

A. Material Selection

Three main materials are commonly utilized for manufacturing bar grating stair treads, namely steel, aluminum, and stainless steel.

1. Steel: One of the most widely used materials, steel, provides exceptional strength and durability, making it suitable for heavy-duty applications. While it might be heavier than its counterparts, its toughness and ability to withstand substantial loads make it a favorite in many industrial settings.

2. Aluminum: A lightweight yet sturdy alternative to steel is aluminum. Its innate corrosion-resistance and durability make it ideal for areas where weight considerations are essential, such as in structures that need to minimize overall load or those exposed to corrosive elements.

3. Stainless Steel: For environments that pose harsh conditions or exposure to corrosive chemicals, stainless steel becomes an optimal choice. Its superior resistance to corrosion and rust ensures long-term durability, even in the most challenging settings.

B. Different Types of Bar Grating Patterns

There’s a variety of patterns available when it comes to bar grating, each offering unique advantages:

| Welded Steel Grating | 🛠️This robust and economical pattern involves welding the bearing bars and cross rods, creating a high-strength grating ideal for various applications. It’s durable, reliable, and can withstand considerable wear and tear. |

| Press-Locked Grating | ⚙️If aesthetics are a consideration, press-locked grating offers a more uniform and visually appealing look. The bearing bars and cross rods are mechanically interlocked, providing excellent lateral stability and a smoother appearance, making it a popular choice for commercial and architectural applications. |

| Swage-Locked Grating | 🔧Constructed by mechanically locking the crossbars into pre-punched holes in the bearing bars, swage-locked grating provides an impressive strength-to-weight ratio. |

III. Features of Bar Grating Stair Treads

Bar grating stair treads are lauded for their compelling features, each contributing to their widespread use in industrial applications.

A. High Strength-to-Weight Ratio

This attribute means they provide exceptional load-bearing capabilities without adding unnecessary weight to the structure. This combination is a vital asset in many industrial environments, particularly those requiring robust, heavy-duty flooring solutions without stressing the underlying infrastructure.

B. Versatility in Design and Customization

The possibility to select from various materials and grating patterns allows these treads to be tailored to fit an array of requirements and preferences. This capability ensures that they can meet the demands of different applications, from heavy industrial settings to more visually-focused architectural designs.

C. Anti-Slip Surface and Safety

Safety is paramount in any industrial setting. Bar grating stair treads are designed with an anti-slip surface, providing substantial traction and reducing the risk of slips and falls. This feature, coupled with their strength and stability, offers users peace of mind knowing they are walking on a secure, reliable surface.

D. Long-Lasting and Durable

Durability is another prominent feature of bar grating stair treads. Their robust construction and the use of high-quality materials ensure they withstand the test of time, even under heavy foot traffic and harsh conditions. These treads are built to endure, reducing the need for frequent replacements and maintenance, making them a cost-effective choice in the long run.

E. Open Design for Light, Air, and Drainage

The open-grid design of bar grating stair treads provides benefits beyond safety and durability. This structure allows for the passage of light and air, enhancing visibility and ventilation in the workspace. Additionally, the open design supports effective drainage, preventing water accumulation on the surface, further contributing to safety and longevity.

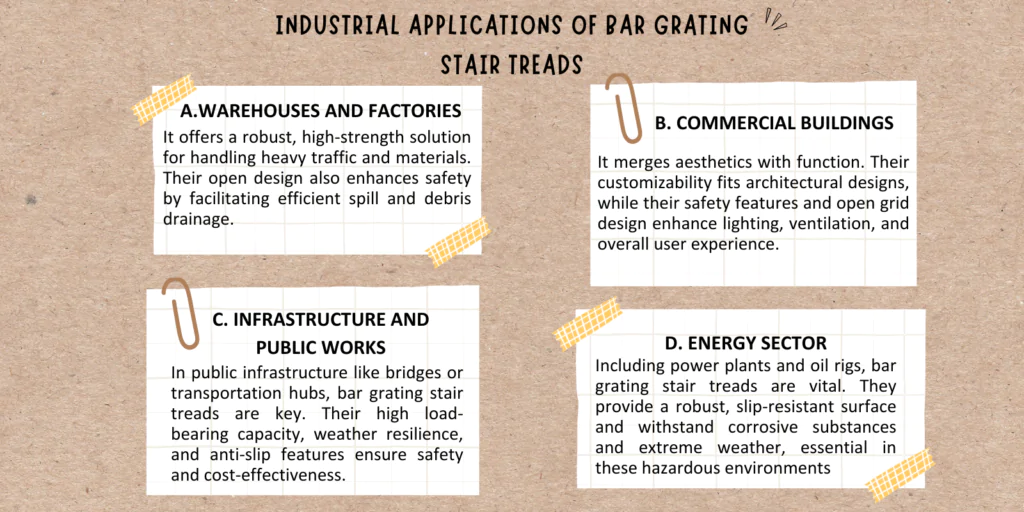

IV. Industrial Applications of Bar Grating Stair Treads

Given their robustness, safety, and adaptability, bar grating stair treads find a myriad of applications across various industries.

- A. Warehouses and Factories

In warehouses and factories, there is a constant need for sturdy and reliable stair treads that can handle heavy foot traffic, equipment, and materials. Bar grating stair treads fulfill this requirement excellently, providing a high-strength, durable solution that withstands the rigors of the industrial environment. Additionally, their open design allows for efficient drainage of spills and debris, promoting a safer workspace.

- B. Commercial Buildings

In commercial buildings, such as offices, shopping malls, and multi-storey car parks, aesthetics become a significant consideration. The ability to customize bar grating stair treads to suit architectural designs, coupled with their functionality and safety features, makes them an attractive choice.

The open grid design also contributes to improved lighting and ventilation in these spaces, enhancing the overall ambiance and user experience.

- C. Infrastructure and Public Works

In the realm of public infrastructure, including bridges, sidewalks, transportation hubs, and public utility buildings, bar grating stair treads are invaluable. Their high load-bearing capacity, resilience to weather, and anti-slip properties ensure public safety, while their low maintenance requirements make them a cost-effective choice for public works.

- D. Energy Sector

In the energy sector, which encompasses areas like power plants, oil rigs, and wind turbines, bar grating stair treads prove essential. They not only offer a sturdy and slip-resistant surface in potentially hazardous environments but also withstand corrosive substances and extreme weather conditions often found in such settings.

In summary, bar grating stair treads’ versatility, safety, and durability not only enhance the operational efficiency of these spaces but also ensure a high level of safety for those using them, making them an invaluable component in these industries.

V. How to Choose the Right Bar Grating Stair Treads

Choosing the right bar grating stair treads for your industrial needs is an essential process, with several key factors to consider.

| Factors for Selection | Description |

|---|---|

| Understanding Load Requirements | Load nature is a primary consideration. Heavy loads require stronger materials such as steel grating. Lighter loads may be suited for aluminum grating. |

| Considering Environmental Conditions | The installation environment significantly influences selection. Corrosive environments favor stainless steel due to its rust-resistant properties. In milder conditions, aluminum or regular steel may suffice. |

| Evaluating Safety Requirements | Safety is paramount. Anti-slip stair treads are crucial in accident-prone industries. Certain grating patterns offer added safety features like better load distribution and improved visibility. |

| Balancing Cost-Effectiveness and Quality | Balancing cost and quality is vital. Higher-quality materials and patterns might have higher initial costs, but their durability and lower maintenance could render them more cost-effective in the long run. |

VI. Installation and Maintenance of Bar Grating Stair Treads

Bar grating stair treads, while highly durable and functional, require careful installation, regular maintenance, and eventual replacement to maintain their optimum performance and longevity.

A. Proper Installation Techniques

The first step towards a long-lasting stair tread is proper installation. This process should be performed by professionals familiar with best practices for the selected material and grating pattern. Correct installation includes ensuring proper fit and secure attachment, as improper installation could lead to safety risks and premature wear.

B. Regular Maintenance and Inspections

Routine maintenance and inspections are essential to keep the stair treads in top condition. This process involves cleaning debris and spills to prevent slipping hazards, checking for signs of wear or damage, and promptly addressing any issues found. Additionally, in corrosive environments, regular cleaning can help prolong the life of the stair treads.

C. Replacement and Disposal

Even with the best care, there will come a time when the stair treads need to be replaced. Disposal should be handled responsibly, considering the material’s recycling potential and local waste regulations. The replacement process should be done promptly and professionally to maintain safety and operational efficiency.

D. Personal experience

Based on my personal experience with bar grating stair treads in a large warehouse, I can attest to the importance of regular maintenance and inspections. We once identified a section with early corrosion during a routine check, likely from a chemical spill that wasn’t promptly cleaned.

Though not immediately visible, closer inspection revealed thinning grating. We swiftly replaced the damaged section, potentially averting an accident. This experience underscores the importance of regular inspections in maintaining safety, preventing accidents, and ensuring the longevity of bar grating stair treads in an industrial setting.

VII. Conclusion

Bar Grating Stair Treads are undeniably a reliable choice in various industrial contexts. Combining strength, safety, and versatility, they cater to a plethora of needs. It’s about understanding your specific requirements, choosing the right materials and patterns, and maintaining them properly to reap the maximum benefits. In a world that prioritizes safety and efficiency, Bar Grating Stair Treads have firmly established their importance.