Introduction

Black steel grating is an ideal material for environments that require corrosion resistance, non-sparking characteristics, or a high level of durability. It is fabricated using a variety of processes, including stamping, welding, and riveting.

Manufactured black steel grating provides the strength, load-bearing capacity, and safety features needed in industrial settings. Special manufacturing processes can also be used to customize the product to meet the specific needs of individual applications.

The superior quality of black steel grating makes it perfect for areas where saltwater exposure is common or where heavy pedestrian or vehicle traffic is expected. For these reasons and more, it’s easy to see why black steel grating is a popular choice among manufacturers.

This article will be all about black steel gratings, their advantages, uses, and fabrication.

What is black steel grating?

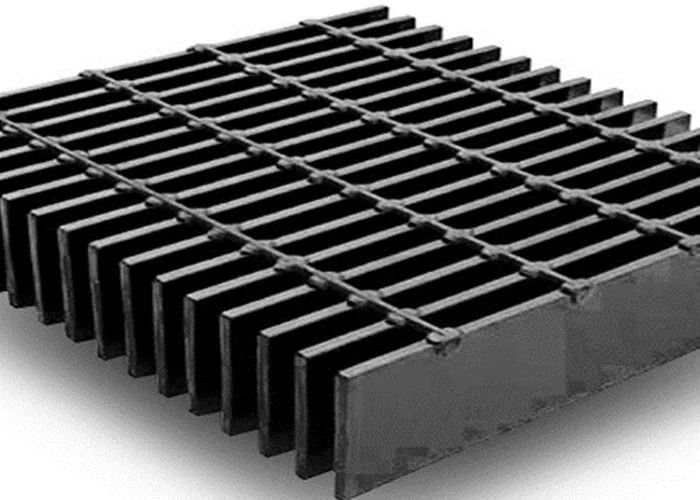

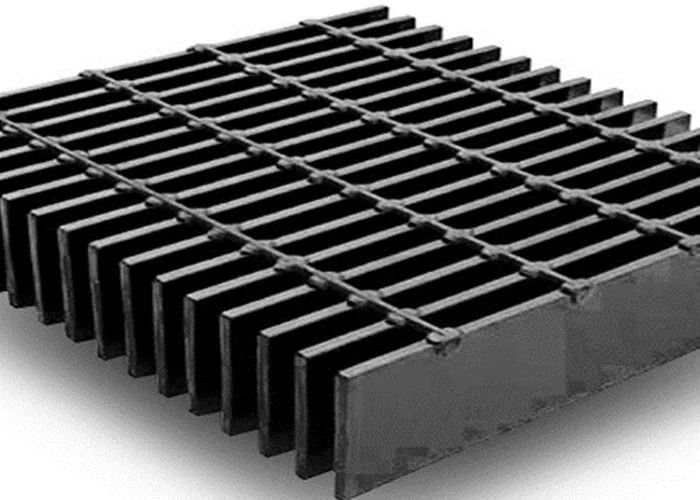

Black steel bar grating is a type of metal grating which is made of uncoated, lightly oiled black steel. It can be used for floors, platforms, stairs, stair treads, walkways, work platforms, and other industrial uses.

The open grid construction makes it ideal for drainage applications as it allows light, air, and liquids to pass through with ease while providing superior load-bearing strength. Its galvanized finish makes it corrosion-resistant and durable even in extreme conditions.

This type of grating is easy to install and maintain making it an ideal choice for many industrial needs. It provides a safe non-slip surface that can effectively support heavy loading conditions such as forklifts or pedestrian traffic. Along with its economical price point, black steel grating offers versatility and strength making it one of the most popular materials used in industrial applications.

It is also commonly used in outdoor applications as its open design can withstand any weather condition. With its numerous advantages, black steel grating is the perfect solution for your industrial requirements.

Advantages of black steel grating

Black steel grating is a useful and convenient material for many industrial applications. It offers several advantages that make it an ideal choice for creating durable, low-maintenance workspaces and structures.

First, black steel grating has proven to be highly resistant to corrosion and oxidation, making it the perfect material for creating long-lasting structures in harsh environments. Its resistance gives black steel grating a longer lifespan than other materials when placed under continuous stress or in places exposed to corrosive chemicals or extreme weather conditions.

Second, black steel grating is highly durable due to its strong construction d a thick powder coating of protective paint. This makes it suitable for heavy-duty industrial applications such as footbridges, bearing bars, cross bars, walkways, mezzanines, and platforms. The metal construction offers a sturdy support structure that can handle significant weight and movement.

Third, black steel grating is very easy to install and maintain. It can be cut into any size or shape depending on the requirements of the project, making it a versatile material for a range of applications. Additionally, surface secondary cleaning is simple and requires only minimal effort; regular wiping down with a cloth is usually enough to keep the metal looking new.

Finally, black steel grating has aesthetically pleasing properties; its dark color gives industrial structures an eye-catching look that stands out from other materials. This makes it ideal for situations where appearance matters but strength is still necessary.

Overall, black steel grating provides many advantages that make it an ideal material for industrial applications. Its corrosion and oxidation resistance, strong construction, ease of installation, and aesthetic appeal make it a reliable solution that can maintain its condition even in harsh conditions.

How to make black steel grating

Black steel grating is a type of metal grating that is made out of black steel. It is a strong and durable type of grating that is often used in industrial and commercial settings. Black steel grating can be made using a few simple steps:

- First, you will need to purchase some black steel sheeting. You can find this at most hardware stores or online retailers.

- Next, you will need to measure the size of the area where you want to install the grating. You will need to cut the sheeting to size using a metal saw or shears.

- Once the sheeting is cut to size, you can begin drilling the holes for the screws. You will need to drill evenly-spaced holes around the perimeter of the sheeting. Make sure to drill holes in both the top and bottom of the sheeting.

- Next, you will need to install the screws. Use a screwdriver to insert the screws into the drilled holes. Be sure to use enough screws to securely hold the sheeting in place.

- Finally, you can install the black steel grating overtop of the screws. Make sure that it is level and secure before walking on it.

By following these steps, you can successfully install black steel grating in your space. It is a simple, yet effective way to add strength and stability to any area. With the right materials and tools, anyone can easily install black steel grating.

Tips for manufacturing black carbon steel gratings

When manufacturing black steel gratings, it is important to ensure that the materials used are of high quality and meet the necessary safety standards. The galvanized steel should be cut accurately to size before being welded together for strength and durability.

Gratings need to be uniform in size and shape with all edges properly aligned. Quality control checks should be conducted periodically throughout the process of hot dip galvanized steel to check for any inconsistencies or defects.

In addition, protective coatings such as epoxy paints and galvanizing can also be applied which will help protect against corrosion and other damage caused by extreme weather conditions. Finally, any black steel grates that are produced should have been tested according to the relevant safety specifications beforehand.

Following these steps will ensure that your black steel Indiana gratings are manufactured safely and effectively.

How to use black stainless steel gratings

Black steel gratings are often used in a variety of settings such as industrial, commercial, and residential. They provide strength and durability for areas that require extra security or protection from heavy foot traffic. For safety reasons, it is important to properly install black steel grates so they can remain secure over time.

When installing black steel gratings, it is recommended to use galvanized fasteners to ensure the highest level of corrosion resistance. Make sure the area around where you will be installing the grate is clear of debris, including any nails or other sharp objects that could cause damage to the grate material.

Also, check the depth of your base surface to make sure it fits with the size and weight of your grating system before installation begins.

When setting the grating into place, use a level to ensure that it is level and secure. Be sure to check for any gaps between the grates and concrete or other surfaces as these can cause water accumulation or pooling, which can lead to rust.

Place two screws in each bearing bar of your grate. Make sure they are firmly held in place by tightening them securely with a screwdriver or drill bit.

Finally, after all, fasteners are tightened, it is recommended to apply sealant around joints and where the grating meets other surfaces for maximum protection from moisture build-up. By following these steps, you will be able to effectively install black steel gratings for long-term security and durability.

Conclusion

Manufacturing black steel gratings require specialized machinery and knowledge to produce a quality product. Due to the high temperature involved in abrasive blasting manufacturing, it is important to use proper safety precautions and follow the manufacturer’s instructions.

In conclusion, manufacturing black steel gratings is a difficult process that requires specialized equipment and experience to ensure a safe and successful product. With the right knowledge and understanding of the process, it is possible to create quality grates for many applications.

The result will be worth the effort as long as all safety considerations are taken into account. By taking these precautions manufacturers can guarantee high-quality products at an affordable price for their customers.

Manufacturing black bare steel gratings also involves being aware of local laws and regulations when producing them due to the hazardous nature of molten metal during production.

Thorough research must be conducted before beginning any project to make sure that production meets all standards set out by local and international governing bodies. Depending on the application, additional safety measures may need to be taken to ensure a safe working environment for both employees and customers.