Are you looking for information on how much steel gratings will cost in 2022?

If so, you’ve landed to the right article, where we’ll discuss the factors that affect the cost of steel gratings and give you an estimated price range for different types of steel gratings and projects.

How Much Do Steel Gratings Costs in 2022?

As a quick guide, this table can help you get a rough idea of steel gratings prices:

| Gratings Type | Part Number | Bearing Bar Size | Material | Surface | Finish | Price |

|---|---|---|---|---|---|---|

| Steel bar gratings | 19-W-4 | 1" x 1/8" | Carbon steel | Smooth | Mill Finish | US$26.19 |

| Steel bar gratings | 19-W-4 | 3/4" x 3/16 | Carbon steel | Smooth | Mill Finish | US$32.54 |

| Steel bar gratings | 19-W-4 | 1" x 3/16" | Carbon steel | Smooth | Mill Finish | US$39.68 |

| Steel bar gratings | 19-W-4 | 1" x 1/4" | Carbon steel | Smooth | Mill Finish | US$47.3 |

| Steel bar gratings | 19-W-4 | 1/4" x 3/16" | Carbon steel | Smooth | Mill Finish | US$23.81 |

| Steel bar gratings | 19-W-4 | 3/4" x 1/4" | Carbon steel | Smooth | Mill Finish | US$38.41 |

| Steel bar gratings | 19-W-4 | 1/2" x 1/4" | Carbon steel | Smooth | Mill Finish | US$23.81 |

| Steel bar gratings | 19-W-4 | 3/4" x 1/8" | Carbon steel | Smooth | Mill Finish | US$23.97 |

| Steel bar gratings | 19-W-2 | 1" x 3/16" | Carbon steel | Smooth | Mill Finish | US$42.54 |

| Steel bar gratings | 19-W-2 | 1" x 3/16" | Carbon steel | Smooth | Mill Finish | US$42.54 |

| Steel bar gratings | 19-W-2 | 1-1/4" x 3/16" | Carbon steel | Smooth | Mill Finish | US$52.38 |

| Steel bar gratings | 19-W-2 | 1-1/4" x 3/16" | Carbon steel | Smooth | Mill Finish | US$52.38 |

| Steel bar gratings | 19-W-2 | 1-1/2" x 3/16" | Carbon steel | Smooth | Mill Finish | US$62.06 |

| Steel bar gratings | 19-W-2 | 2" x 3/16" | Carbon steel | Smooth | Mill Finish | US$80.16 |

Note:The above prices are for reference only, please contact us for a detailed quote!

The cost of steel grating can vary widely depending on several factors, including the type and quality of the steel used, the size and complexity of the grating, and the company or supplier you purchase it from.

The small mesh gratings can cost around $4 per square foot, while large industrial gratings can cost upwards of $15 per square foot.

Continue reading! As in this article, we will explain in detail how many different types of steel grating cost and what factors influence the price. We will also provide tips on getting the best-priced steel grating for your application.

What are steel grating, and what are their uses?

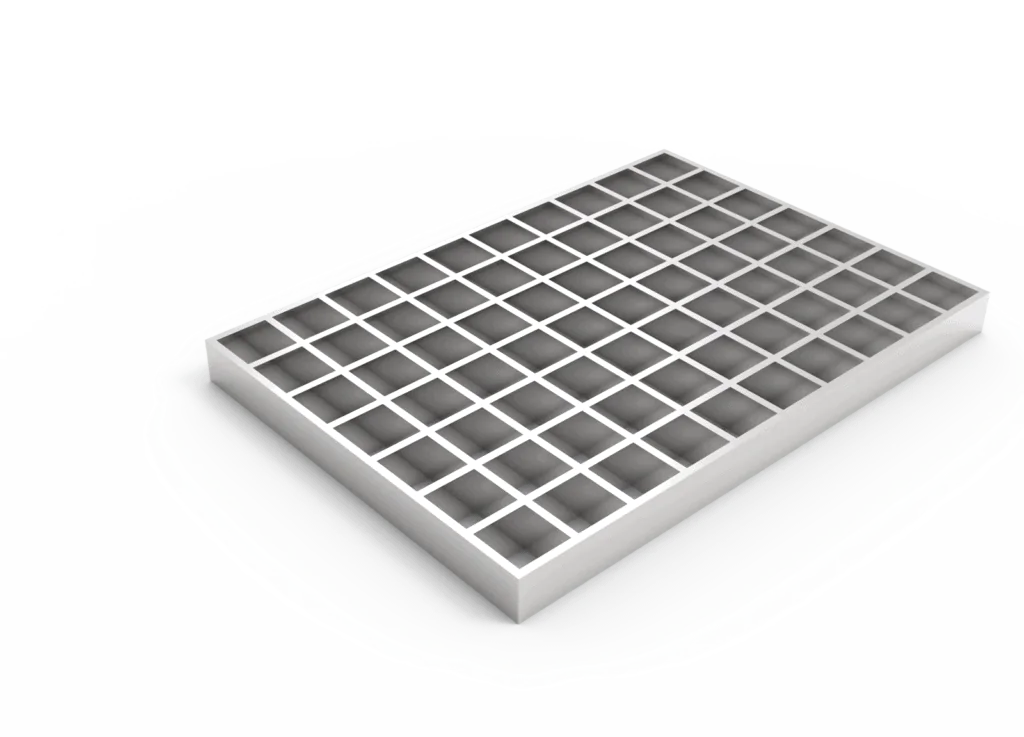

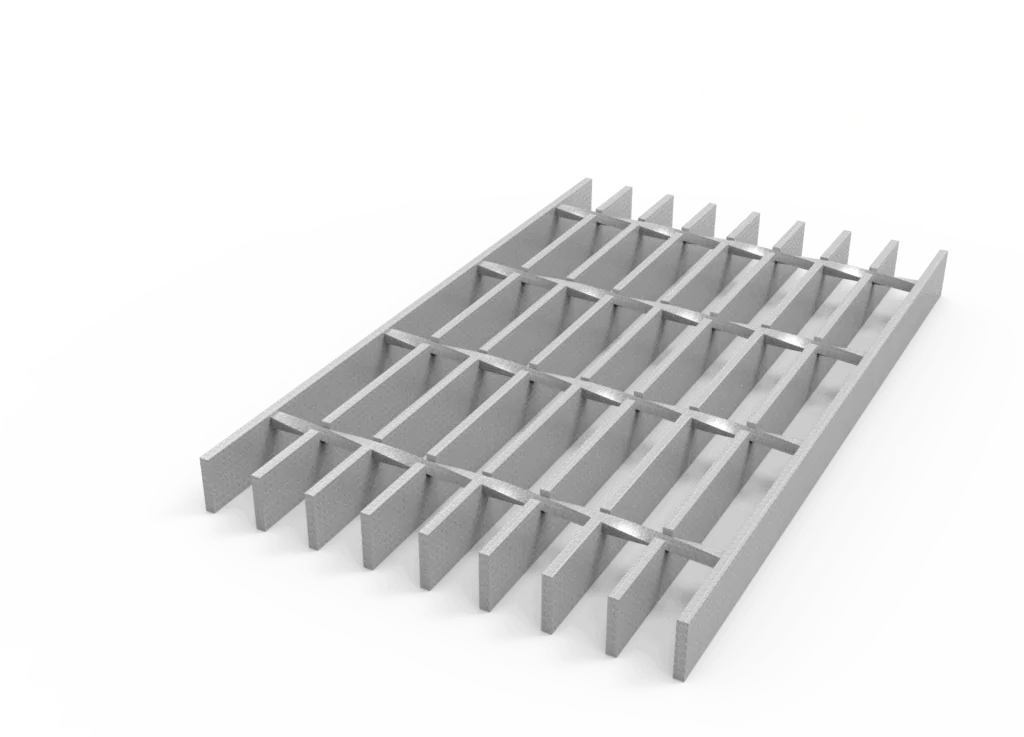

Press locked grating are a steel product produced by welding steel bars together to form a grid-like pattern.

Steel grating are often used in industrial and commercial applications as they are strong, durable, and have a high load-bearing capacity.

Steel grating can be made with different spacing between the bars, and they can also be powder-coated to improve their corrosion resistance.

Press locked grating are used for various purposes, such as industrial flooring and fencing. Besides, they are also used as trench covers, ceilings, platforms, stairs, walkways, sunshade panels, etc.

They are typically made from stainless steel, resistant to rust and corrosion. Steel grating can be used outdoors or indoors and are available in various surface treatment, sizes and thicknesses.

Steel grating are essential to many residential, civil, industrial, and commercial applications.

They are used in various settings, including power plants, chemical plants, oil and gas refineries, food processing plants, and more.

Steel grating can also be found in many public spaces, such as parking garages, parking lots, sidewalks, and stairways.

Categories of Steel Grating and their Price Ranges:

Regarding steel grating, the cost can rely on numerous factors, including the type of steel used and the grade of quality you want.

The most common types of steel grating are galvanized steel and stainless steel grating. Besides, Carbon steel and Aluminum carbon steel grating are also used.

Galvanized steel is made up of iron, zinc, and manganese. It has a rust resistance that rivals stainless steel, which is why it’s so famous for commercial buildings because it’s resistant to corrosion.

Galvanized steel also has a high strength-to-weight ratio, which means you can use less material to do your project if you buy high-quality materials.

Stainless steel is a metal that has been treated using an electrochemical process called electropolishing.

This process makes it resistant to corrosion but not rusting or tarnishing like galvanized does over time if left outdoors without proper maintenance.

The average cost per ton for steel gratings is US$ 1200-US$1300 or $30 to $50 per square foot.

However, these prices can significantly vary depending on various factors, such as manufacturer, gratings type, application, thickness, material, size, finishing, surface treatments, design, application, etc.

Factors that affect the price of steel grating:

The price of a steel bar grating depends on factors such as the material of the grating, its size, the finish applied to it, whether or not it has been coated with paint, and a lot more.

· Material:

The most significant factor affecting the price of steel bar grating is its material.

The cost of steel differs depending on the metal being used: carbon steel is relatively less expensive than stainless steel.

Carbon steel has lower melting points than stainless steel, which can be more easily welded into place without cracking.

The steel grating material type also includes cold rolled, hot rolled, galvanized, and more.

The price of steel, based on the type of material, is high or low. The cost of steel based on hot rolled is high as it is an expensive process.

On the other hand, the price of cold rolled steel is comparatively low.

· Size:

Gratings come in various sizes, such as 1/4 inch, 3/8 inch, and 1/2 inch. Smaller sizes tend to cost less per square foot than large ones do.

This is because fewer raw materials are required for smaller pieces, which means that manufacturers can use cheaper methods for manufacturing them.

· Finish:

Three main types of finishes are used to apply to steel grating. They are paint, primer, and laminating, all of which affect the steel grating’s price.

Paint is the cheapest of all finishes, primer and laminating are expensive, and coating is the most costly. The cost of steel based on paint is low because it is applied altogether.

The price of steel based on priming is high because the coating is done by brush. Laminating is done through a roller, which is an expensive process.

The price of steel based on coating is high because it is done by spray.

· Application:

Carbon steel grating is used in warehouses, supermarkets, gardens, and more. T

hey are also used in different settings in construction, like bridges, buildings, and more.

The price of steel, based on the type of application, is high or low. The application of steel grating depends on the climatic environments of the area in which they are installed.

For example, they might be used in outdoor areas where they have to withstand adverse climatic conditions without getting rusted.

· Safety and quality:

Quality parameters and safety standards are maintained while manufacturing steel grating. These factors affect the price of steel grating.

For example, a steel grating with a poor finish is not sold and is scrapped, while one with a good finish is sold and bought at a higher price.

· Manufacturing cost:

Steel grating are usually made of carbon steel, an expensive material.

Other than that, it is mixed with other materials like Aluminum, iron, and more. All these are costly ingredients that affect the price of steel grating.

The benefits of using steel grating:

Using welded steel grating can give you loads of benefits depending on its application, including:

· Steel grating are durable and long-lasting, so they will last for years, making them a great investment.

· They are easy to clean, so you shouldn’t be concern about cleaning the grating on your ceiling, floor, windows, or stairs daily.

· It is possible to paint or paint over them if you choose, which can be a nice upgrade if you want to change the look of your windows.

· The steel grating are easy in installation and don’t require any specialized tools or extra effort.

· Welded Steel grating can be used as drain cover and prevent water from entering the building and causing damage.

· Installing a serrated steel grating in your home will help protect you from any potential damage caused by a fire or an earthquake.

· They can prevent workers from slipping if used as floor, stair treads, or platforms. Besides, they can protect them from falling into trenches (if used as trench covers) or falling objects if used as a ceiling.

How to choose the suitable steel grating for your needs?

Choosing the suitable serrated steel grating for your needs is a matter of finding the right combination of features, size, and price. To help you, we’ve outlined the following key considerations:

· Size:

Plain Steel grating comes in wide array of sizes. The larger the size, the more load-bearing capacity it has. It will also cost more than smaller sizes due to the higher material costs involved with larger sizes.

· Material:

When choosing a plain steel grating material, consider whether you want to use stainless steel or not. Stainless grates are stronger but costlier than their non-stainless steel grating.

They can also rust if not treated properly, so make sure you’re aware of any potential issues before selecting one type of steel over another!

· Features:

Steel grates have a lot of features that can vary from manufacturer to manufacturer—some come with vents, some come with handles and hinges; some have rubber boots on top for slip resistance, etc.,

so make sure that you know exactly what kind of functionality you’ll need out of it.

· The environment of Application:

Is the product you’re considering going to be exposed to harsh weather conditions? If so, you might want to look for grating with rust-inhibiting properties.

· Durability:

Do you need something that will last a long time? Look for products made from materials that don’t corrode or rust easily.

· Thickness:

The steel grating’s thickness affects how long it lasts before needing replacement and its load-bearing capacity.

A thicker piece of steel will generally last longer than one thinner because they both have the same amount of material to support the weight.

· Area:

What kind of surface will the grating cover? If it covers a large area, you’ll want something that won’t hold water and develop rust spots quickly.

Final Words

So after reading the article, you must have made up your mind and thinking about where to buy steel grating online or in-store.

So, we suggest you buy from ChinaGratings.com.

We offer the most competitive prices in the market, and we have a large selection of steel grating and different types of steel grating, like stainless steel grating, galvanized steel gratings, and many more.

Our website is easy to use. You can browse our catalog to find the best product that suits your needs.