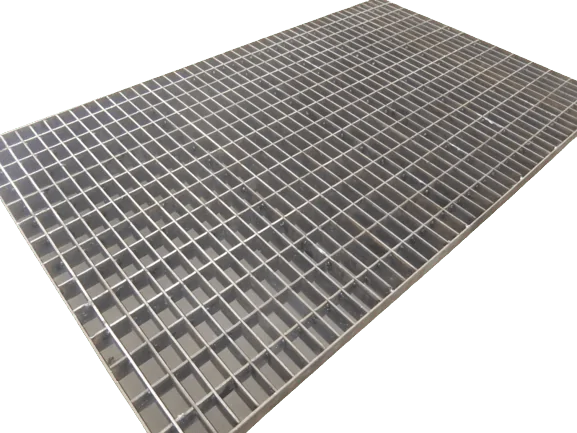

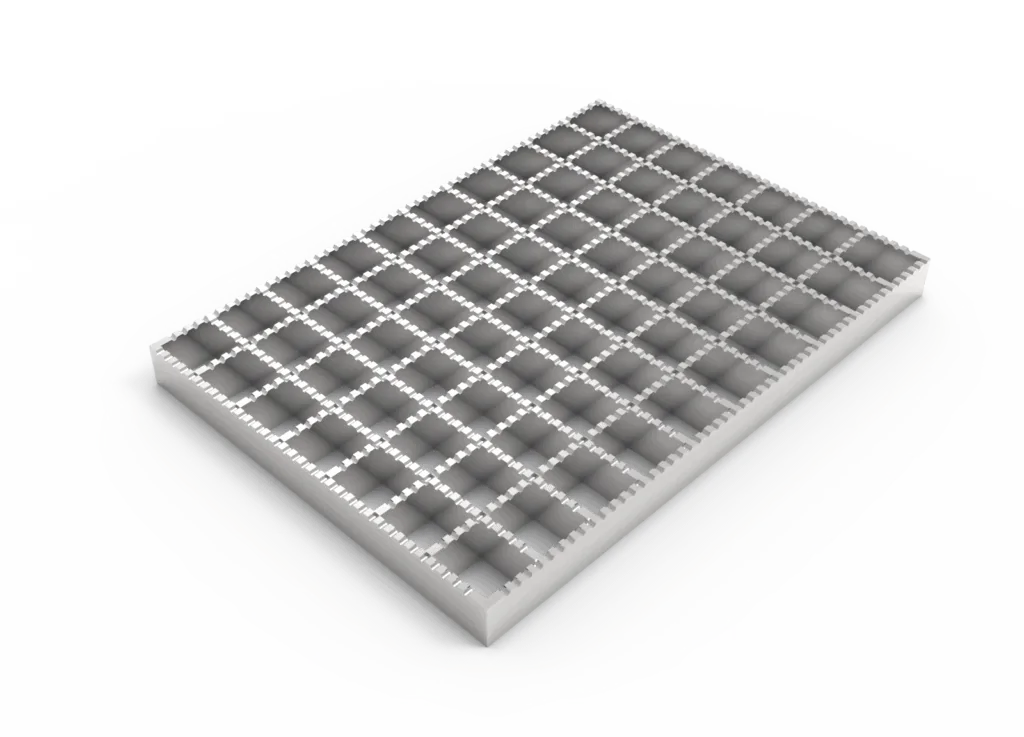

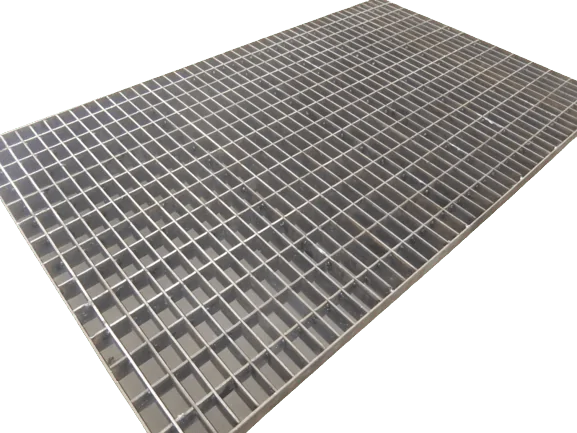

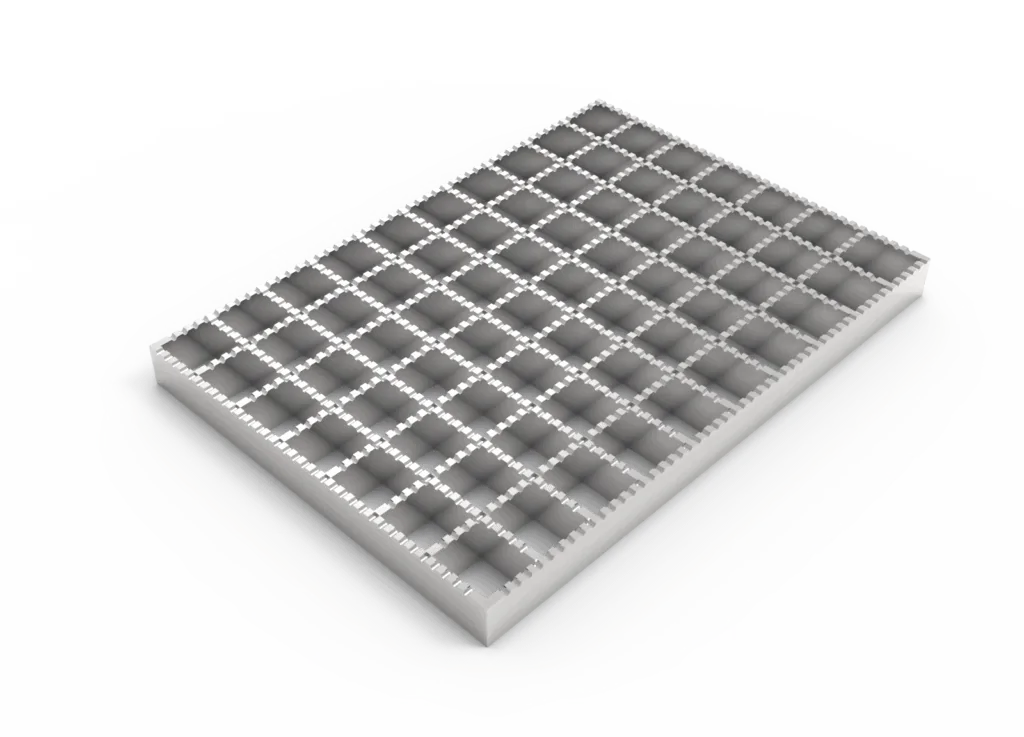

General Introduction To Press-locked Steel Grating: All You Need To Know

- Superior quality press-locked steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

Welded Wire Mesh

Welded Wire Mesh: The Ultimate Solution for Fencing, Construction, and More!

What is Welded Wire Mesh?

Types of Welded Wire Mesh

Galvanized Welded Wire Mesh

Stainless Steel Welded Wire Mesh

PVC-Coated Welded Wire Mesh

Welded Wire Mesh Panels

The Specification of Each Type of Welded Wire Mesh

| Type of Welded Wire Mesh | Mesh Size | Wire Diameter | Width | Length | Surface Finish |

|---|---|---|---|---|---|

| Galvanized Welded Wire Mesh | 1/4"-4" | 0.5-5mm | 0.5-2m | 5-50m | Galvanized |

| Stainless Steel Welded Wire Mesh | 1/4"-4" | 0.5-5mm | 0.5-2m | 5-50m | Stainless Steel |

| PVC-Coated Welded Wire Mesh | 1/4"-4" | 0.5-5mm | 0.5-2m | 5-50m | PVC-Coated |

| Welded Wire Mesh Panels | 1/4"-4" | 0.5-5mm | 1-2m | 2-3m | Galvanized or PVC-Coated |

Material of Welded Wire Mesh

- Low carbon steel: This is a cost-effective option for Welded Wire Mesh that provides good strength and durability. However, it may be susceptible to rust and corrosion over time.

- Stainless steel: This material is highly resistant to rust and corrosion, making it a good choice for industrial and marine environments where the mesh may be exposed to harsh conditions.

- Galvanized steel: This type of material is coated with a layer of zinc, which provides excellent resistance to rust and corrosion. It is commonly used for fencing, animal enclosures, and construction applications.

Roll Size of Welded Wire Mesh

- Width: 0.5-2m

- Length: 5-50m

Tensile Strength of Welded Wire Mesh

- Low carbon steel: 40-60 kN/m

- Stainless steel: 70-90 kN/m

- Galvanized steel: 50-70 kN/m

Coating of Welded Wire Mesh

- PVC: This coating provides a layer of protection against rust and corrosion, as well as added durability. It is commonly used for fencing and animal enclosures.

- Galvanized: This coating involves applying a layer of zinc to the mesh, which provides excellent resistance to rust and corrosion. It is commonly used for fencing, animal enclosures, and construction applications.

The application of Welded Wire Mesh

- Fencing: This may require a certain mesh size and coating to provide the necessary level of security and protection.

- Animal enclosures: This may require a certain mesh size and coating to ensure the safety and well-being of the animals.

- Construction: This may require a certain mesh size and material to provide the necessary strength and durability for the intended use.

| Application | Mesh Size | Wire Diameter | Material | Coating |

|---|---|---|---|---|

| Fencing | 1/2"-2" | 1.2-2.5mm | Low carbon steel or galvanized steel | Galvanized or PVC |

| Animal enclosures | 1/2"-2" | 1.2-2.5mm | Low carbon steel or galvanized steel | Galvanized or PVC |

| Construction | 2"-4" | 2.5-5mm | Low carbon steel or stainless steel | Galvanized or PVC |

FAQs for Welded Wire Mesh

Welded wire mesh is a type of metal screen composed of intersecting wires that are welded together at their contact points. It forms a grid-like pattern and is commonly used in construction, fencing, industrial applications, and concrete reinforcement.

Welded wire mesh offers several benefits, including high strength and durability, uniformity in mesh size and shape, resistance to corrosion, ease of installation, and versatility in various applications. It provides structural support, prevents cracking in concrete, and offers security and containment in fencing.

Welded wire mesh comes in various types, including galvanized welded wire mesh (coated with a layer of zinc to enhance corrosion resistance), PVC-coated welded wire mesh (provides additional protection against rust and corrosion), and stainless steel welded wire mesh (offers excellent durability and resistance to rust).

To select the appropriate welded wire mesh, consider factors such as the intended application, required strength and durability, mesh size (the spacing between wires), wire gauge (the thickness of the wires), and the environment in which the mesh will be installed. Consulting with a professional or supplier can help ensure the right choice.

Proper maintenance of welded wire mesh involves regular cleaning to remove debris, dirt, and rust, particularly in outdoor installations. If the mesh gets damaged, it should be repaired promptly to prevent further issues. Depending on the coating (if any), following the manufacturer’s guidelines for cleaning and maintenance is recommended.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397