Introduction

Welded steel grating is a type of steel railing that is commonly used in construction, engineering, and manufacturing industries.

It has a variety of advantages over other types of steel railing, including durability, strength, and versatility.

If you’re looking for a strong, durable option for your next project, welded steel grating may be the perfect choice.

Let’s take a closer look at what welded steel grating is and some of its advantages.

What Are The Welded Steel Grating?

Welded steel grating is made of carbon steel or stainless steel. It is also available in aluminum and fiberglass.

Continue reading to learn more about the welded steel grating.

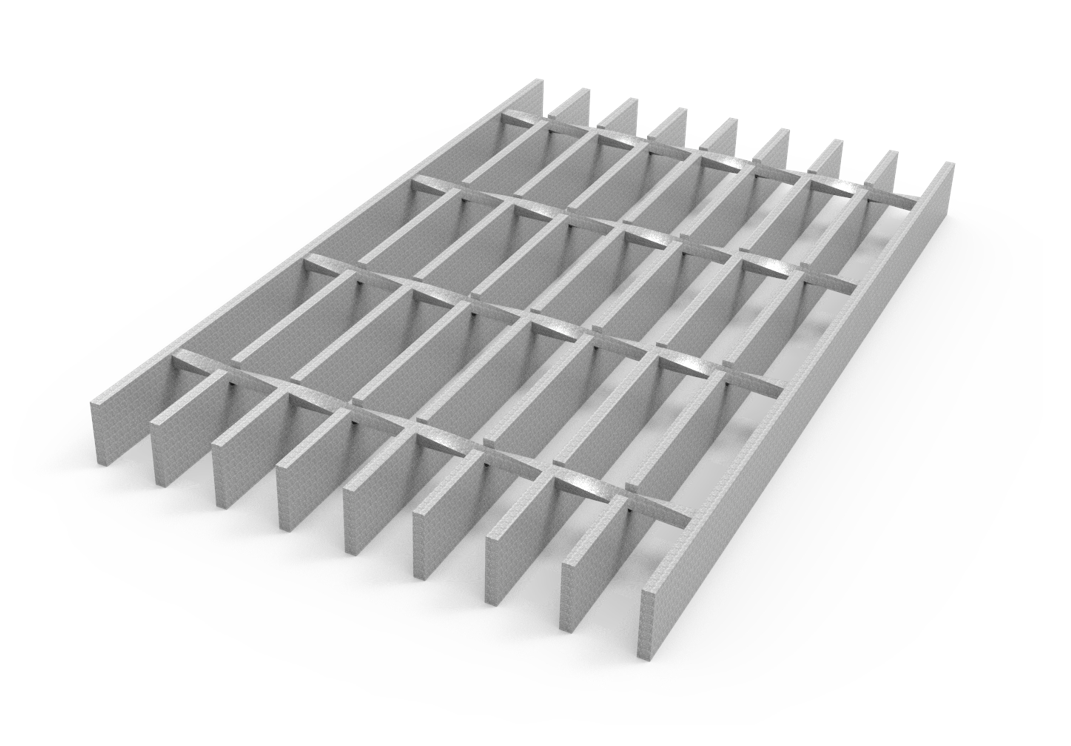

Welded steel grating is a series of bearing bars welded to perpendicular cross bars to form a load-bearing panel.

The spacing between the bearing bars is typically 3/16″, 1/4″, 3/8″, or 1/2 inches. The cross bars are available in 4″, 6″ or 8″ widths and are either round, square, or twisted square.

Welded steel grating is manufactured by a resistance-weld process. The bearing bars and cross bars are electrically resistance welded together. A grating panel is then cut to size and packaged for shipment.

The Advantages Of Using Welded Steel Grating!

Welded steel grating is a versatile and economical product that has many advantages over other types of steel railing. Here are just a few of the advantages of using welded steel grating:

1. Strength And Durability:

Welded steel grating is incredibly strong and durable. It is designed to withstand heavy loads and traffic, making it a great choice for both commercial and industrial applications.

2. Versatile:

Welded steel grating is versatile and can be used for a variety of applications, including construction, engineering, manufacturing, and more. Also, it is available in a variety of sizes, colors, and styles to suit your specific needs.

3. Economical:

Welded steel bar grating is an economical choice for many projects. It is a cost-effective alternative to other types of steel railing, and it can be used in a variety of applications.

In addition, welded steel grating is easy to install and requires minimal maintenance, making it a cost-effective choice for your next project.

4. Low Maintenance:

Welded steel bar grating is a low-maintenance option for many projects. It is designed to withstand heavy loads and traffic, and it requires minimal maintenance.

If you’re looking for a low-maintenance option for your next project, welded steel grating is a great choice.

5. Easy To Install:

Welded steel bar grating is easy to install, making it a great choice for many projects. As it is easy to install, it can be used in a variety of applications, including construction, engineering, and manufacturing. In addition, welded steel grating is available in a variety of sizes, colors, and styles to suit your specific needs.

6. Aesthetically Pleasing:

Welded steel gratings is available in a variety of colors, styles, and sizes to suit your specific needs. It is also an aesthetically pleasing option for many projects.

If you’re looking for an aesthetically pleasing option for your next project, welded steel grating is a great choice.

How To Install Welded Steel Grating?

Before you begin, it is important to note that welded steel gratings must be installed by a qualified professional. Installation instructions vary depending on the type of grating you have purchased. However, there are general tips that can help you during the installation process:

1. Proper Tools:

In order to properly install welded steel gratings, you will need a few tools. These tools include a tape measure, a level, a hammer, and a wrench. So, make sure you have these tools on hand before you begin the installation process.

2. Layout:

Before you begin the installation process, it is important to properly layout you’re welded steel grating. This will ensure that your grating is installed correctly and securely.

3. Positioning:

Once you have laid out your welded steel gratings, you will need to position it correctly. This step is critical in ensuring that your grating is installed correctly and securely.

In order to position your grating correctly, you will need to mark the center of each bar.

4. Drilling:

After you have positioned your welded steel gratings, you will need to drill holes in the grating. These holes will be used to secure the grating in place.

In order to drill the holes, you will need a power drill and a drill bit that is the same size as the fasteners you will be using.

5. Securing:

After you have drilled the holes, you will need to secure the grating in place. In order to do this, you will need to use fasteners. These fasteners can be bolts, screws, or nails.

6. Leveling:

Once you have secured the grating in place, you will need to level it. This step is critical in ensuring that your grating is installed correctly and securely.

In order to level your grating, you will need to use a level.

The Different Types Of Welded Steel Grating Products!

There are many different types of welded steel grating products available on the market today. These products vary in terms of their size, shape, and style.

Here are a few of the most popular welded steel grating products:

1. Standard Grating:

The standard grating is the most popular type of welded steel grating product. In terms of size, the standard grating is available in 3′, 4′, and 5′ widths. In terms of shape, the standard grating is available in rectangular, square, and round shapes.

2. Heavy-Duty Grating:

The heavy-duty grating is a great choice for projects that require a stronger grating. Heavy-duty gratings are available in 4′, 5′, and 6′ widths. So, if you need a stronger grating for your project, heavy-duty grating is a great option.

3. Light-Duty Grating:

The light-duty grating is a good choice for projects that do not require heavy-duty grating. Light-duty gratings are available in 3′, 4′, and 5′ widths. At 3′ wide, the light-duty grating is the narrowest grating option.

4. Walkway Grating:

The walkway grating is a great choice for projects that require a grating that can support heavy traffic. However, the walkway grating is also a good choice for projects that require a grating that is slip-resistant.

5. Handrail Grating:

The handrail grating is a great choice for projects that require a grating with a handrail. Handrail gratings are available in 4′, 5′, and 6′ widths. These gratings can be used on stairs, walkways, and ramps.

There are many different types of welded steel grating products available on the market today.

These products vary in terms of their size, shape, and style. But, no matter what type of welded steel grating product you need, you’re sure to find it at Steel Grating Depot.

Applications For Welded Steel Grating!

Welded steel grating is a versatile product that can be used for a variety of applications. Some of the most popular applications for welded steel grating include:

1. Walkways:

Welded steel grating is a great choice for walkways. The grating provides a slip-resistant surface that can be used in a variety of different settings.

2. Stair Treads:

Welded steel grating is also a great choice for stair treads. Make sure your stair treads are up to code with a welded steel grating.

So, if you need a slip-resistant surface that can stand up to heavy traffic, welded steel grating is the perfect choice.

3. Mezzanines:

Welded steel grating is also a popular choice for mezzanines. Mezzanines are often used in warehouses and industrial settings. And welded steel grating is the perfect choice for these types of applications.

4. Ramps:

Ramps are another common application for welded steel grating. The grating provides a slip-resistant surface that can be used in a variety of different settings.

5. Drainage Grates:

Welded steel grating is also a popular choice for drainage grates. You can find welded steel grating in a variety of different sizes and styles.

So, if you need a drainage grate that meets your specific needs, you’re sure to find it at Steel Grating Depot.

FAQs About Welded Steel Grating!

Q. What Is Welded Steel Grating?

A. Welded steel grating is a type of grating that is made from Welded steel.

Q. What Are The Benefits Of Welded Steel Grating?

A. The benefits of welded steel grating include its strength, durability, and slip resistance.

Q. What Are The Applications For Welded Steel Grating?

A. Some of the most popular applications for welded steel grating include walkways, stair treads, mezzanines, ramps, and drainage grates.

Q. Where Can I Find Welded Steel Grating?

A. You can find welded steel grating at Steel Grating Depot. If you have any questions about our products or services, please don’t hesitate to contact us.

Q. How Can I Order Welded Steel Grating?

A. You can order welded steel grating by contacting us or by visiting our website. We will be happy to help you select the perfect product for your needs.

Conclusion

Welded steel grating is made of welded steel bars, which are strong and durable. It has a variety of applications and benefits that make it a popular choice for many industries.

If you’re looking for a sturdy, reliable material to use in your next project, welded steel grating may be the perfect option for you. Contact SUNJ GRATING LIMITED today to learn more about our products and services.