Welded Steel Grating Supplier

General Introduction To Welded Steel Grating: All You Need To Know

- Superior quality welded steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

General Introduction To Welded Steel Grating

Welded bar grating, also known as metal open bar grating, is a type of grating that can be manufactured from a variety of materials, including carbon steel, aluminum steel, or stainless steel. The bearing bars and cross bars are welded together under high heat and pressure, creating a durable joint. There are two types of steel bar gratings: smooth and serrated.

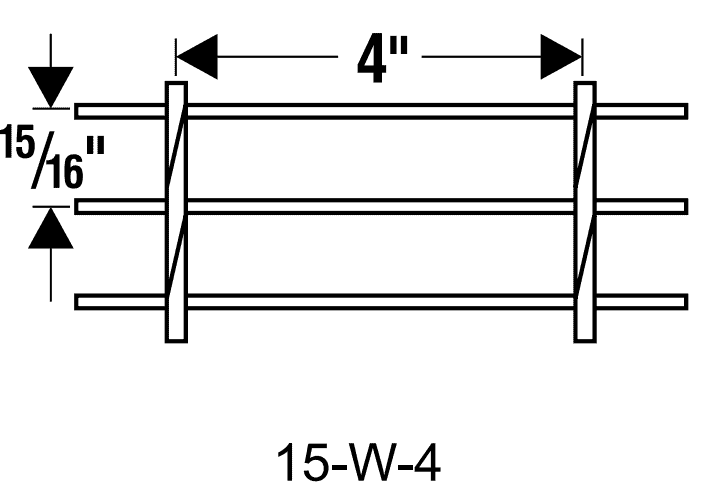

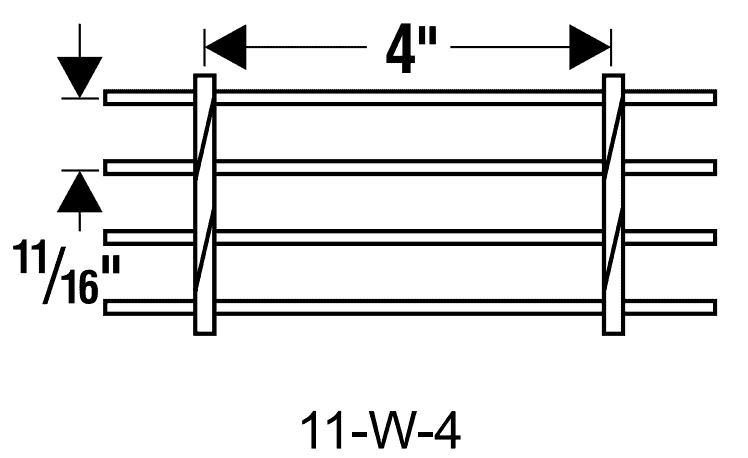

Welded Bar Grating comes in two types: “W” Welded Steel and “WS” Welded Stainless Steel. It can be obtained with bearing bar spacing options ranging from 19/16 inches (1-3/16 inches) to 7/16 inches on center. The cross bars can be placed at either 4 inches or 2 inches on center.

Welded Steel Grating Specification

Our hot selling Welded Steel Grating

SUNJ Grating is the best place to go for all your metal grating needs. We have over 15 years of experience and our team will be happy help you with any welding, shearing or cutting project that comes up!

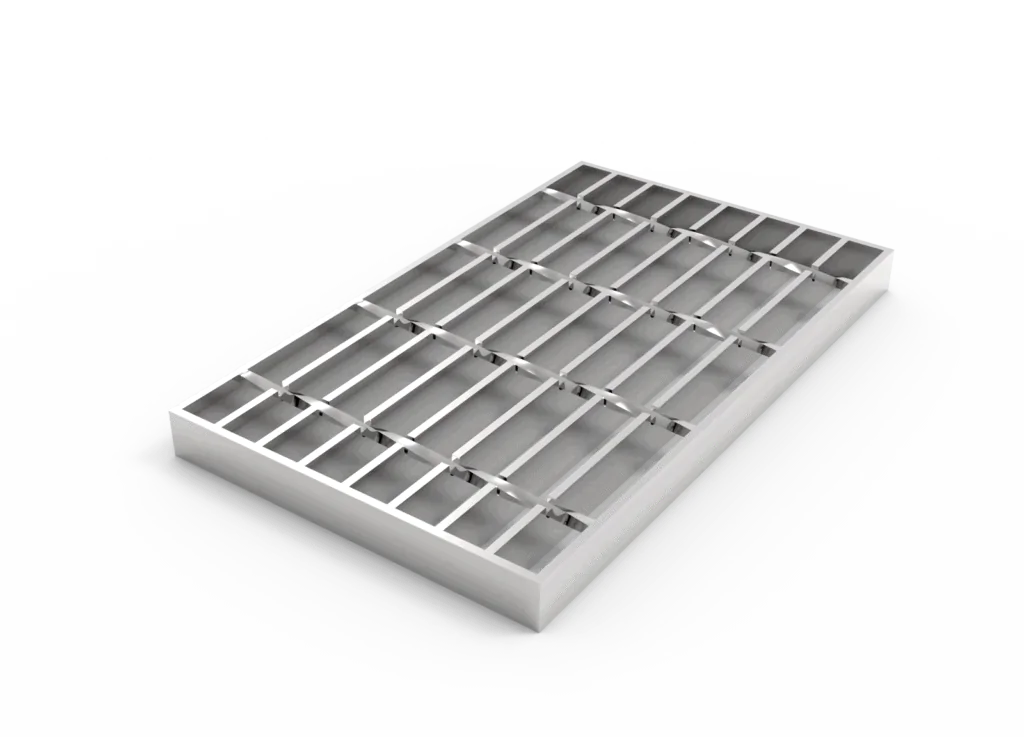

Plain welded steel grating

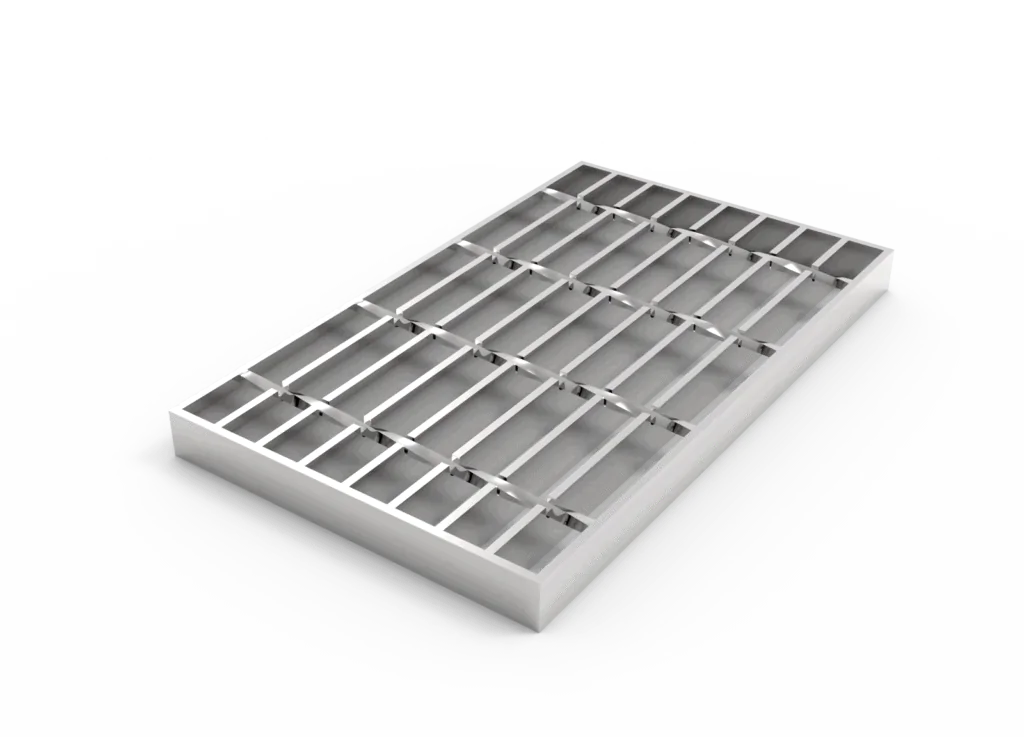

Serrated welded steel grating

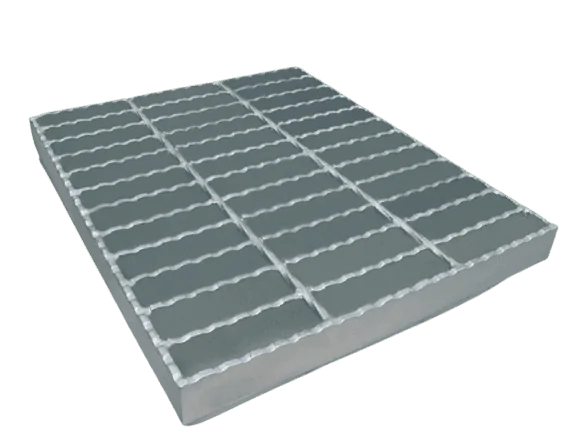

"WS" Welded Steel Grating

Why choose Welded Steel Grating from us?

We offer a wide range of products, including bar grating, stair treads, trench covers, etc. Our products are available in a variety of materials, including carbon steel, stainless steel, and aluminum. And they can be customized according to your specific requirements.

We have a team of professional engineers who can provide you with the most suitable grating solutions based on your specific needs.

Types of Welded Steel Grating

Before understanding the types of welded steel grating, it is necessary to know what steel grating is. In simple terms, steel grating is a series of metal bars positioned at equal intervals and perpendicular to each other.

The spaces between the metal bars allow water, light, air, and heat to pass through. Steel grating is used in a variety of industries for different applications because it is easy to clean, maintain and install.

Type "W" Welded Steel Grating

The most common type of steel grating is the “W” welded steel grating. This type of steel grating is made by welding steel bars to each other at their intersections. The “W” welded steel grating is available in a wide range of sizes and bar thicknesses.

The most common size of the “W” welded steel grating is 1-3/16″ x 3″ (1.58″ centers). The bar-thickness of the “W” welded steel grating ranges from 1/8″ to 3/16″.

In the “W” welded steel grating, the bearing bars are notched so that they can be easily fastened to the supporting members. The cross bars of the “W” welded steel grating are also notched so that they fit snugly into the bearing bars.

Type "WS" Welded Stainless Steel Grating

The “WS” welded stainless steel grating is very similar to the “W” welded steel grating, except that the “WS” welded stainless steel grating is made of stainless steel instead of carbon steel. It is available in the same sizes and bar thicknesses as the “W” welded steel grating.

The advantage of the “WS” welded stainless steel grating is that it is more corrosion resistant than the “W” welded steel grating.

On the other hand, the “WS” welded stainless steel grating is more expensive than the “W” welded steel grating. However, if you are looking for steel grating that will withstand harsh environments; the “WS” welded stainless steel grating is a good choice.

Plain-type welded steel gratings

Welded steel gratings are created by welding metal grids together. The most common type of welded steel grating is the plain style, which features perpendicular bars running in both directions. This type of grating is strong and durable, making it a popular choice for industrial and commercial applications.

Serrated-style welded steel gratings

Another popular type of welded steel grating is the serrated style, which features bars that are notched or grooved. This type of grating provides extra grip and traction, making it ideal for use in areas where there may be oil or grease present.

The Features of Welded Steel Grating

| Specification | Options |

|---|---|

| Material | Carbon steel, Stainless steel |

| Surface treatment | Galvanized, Mill finished, Painted, Powder coated |

| Surface type | Standard plain surface, Serrated surface |

| Bearing bar type | Plain bearing bar, Serrated bearing bar |

| Standard pitch | 50 mm, 100 mm |

Welded Steel Grating Common Specification

| Item | Bearing Bar Size | Cross Bar Diameter | Bearing Bar Spacing | Cross Bar Spacing |

|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | |

| G203/30/100W | 20 x 3 | 6 | 30 | 100 |

| G205/30/100W | 20 x 5 | 6 | 30 | 100 |

| G253/30/100W | 25 x 3 | 6 | 30 | 100 |

| G255/30/100W | 25 x 5 | 6 | 30 | 100 |

| G323/30/100W | 32 x 3 | 6 | 30 | 100 |

| G325/40/100W | 32 x 5 | 6 | 40 | 100 |

| G353/40/100W | 35 x 3 | 6 | 40 | 100 |

| G355/40/100W | 35 x 5 | 6 | 40 | 100 |

| G403/40/50W | 40 x 3 | 6 | 40 | 50 |

| G404/40/50W | 40 x 4 | 6 | 40 | 50 |

| G405/40/50W | 40 x 5 | 6 | 40 | 50 |

| G455/30/50W | 45 x 5 | 10 | 30 | 50 |

| G503/30/50W | 50 x 3 | 10 | 30 | 50 |

| G505/30/50W | 50 x 5 | 10 | 30 | 50 |

| G555/30/50W | 55 x 5 | 10 | 30 | 50 |

| G605/30/50W | 60 x 5 | 10 | 30 | 50 |

| G655/30/50W | 65 x 5 | 10 | 30 | 50 |

Welded steel bar grating size types

The Process Flow for Welded Steel Gratings

Welded steel gratings do widely use in various industries such as petrochemical, power plant, wastewater treatment, and other industrial fields. Because of their durability and anti-corrosive properties, they often operate in areas with a high chance of chemical or other corrosive substances coming into contact with the grating. Let’s take a look at the process flow of welded steel gratings!

Step 1: Cut The Steel Plates:

According to the drawings and requirements, cut the steel plates into strips of different widths with a shearing machine or a plasma cutting machine; after this, the burrs on the cutting surface should remove. Otherwise, it will affect the appearance quality of the gratings. On the other hand, it will also increase the welding workload and even cause the failure of automatic submerged arc welding due to insufficient penetration depth.

Step 2: Making The Frames:

The steel strips are then cut to length and welded to form the framework of the grating. This step is essential because it will determine the strength and stability of the grating. Without this step, the grating would be too weak to support any weight. Once it is welded, the frame is then placed in a jig to ensure that it is of the correct size and shape.

Step 3:Welding The Crossbars:

The crossbars are then welded to the frame, perpendicular to the bearing bars. The distance between the crossbars is generally around 30-100mm. This step is vital because it will determine the stability and strength of the grating.

Step 4:Pre-Welding:

Both sides of the steel strip are welded with a welding machine to form a flat steel strip, which is then cut to length and developed into a U-shaped or V-shaped cross section. By using this method, the pre-welding can improve the welding quality of the gratings and make the gratings more beautiful in appearance. Also, the gratings will be less susceptible to corrosion.

Step 5:Crossbar Rolling:

Passing the pre-welded steel strips through a crossbar rolling machine to form a W-shaped or T-shaped cross-section. This step of welded steel gratings is to make the gratings more stable and strong. For this reason crossbar rolling process flow need to check properly.

Step 6:Product Finishing:

After completing all the steps, the product will be sent to the finishing department for surface treatment. The standard surface treatments are hot-dip galvanizing, electro-galvanizing, and powder coating. These surface treatments can extend the service life of the gratings by 2-3 times. Furthermore, this makes the gratings more aesthetically pleasing.

Step 7:Packaging(1 days)

To ensure that the products are not damaged during transport, we use high-quality packing materials.the packing of steel gratings requires special care and attention. Be sure to wrap each grate in a layer of plastic film, place them in a box or crate, and fill the gaps between the grates with packing material such as styrofoam peanuts or bubble wrap. Seal the box or crate with tape and label it with the contents and the date. These packing tips will help to ensure that your steel grates are protected from rust and corrosion during storage or transportation.

The Advantage of Our Welded Steel Gratings

Strong, durable, and have a high load-bearing capacity.

Easy to install and does not require any special tools or equipment.

Slip-resistant and have a high degree of safety.

Low maintenance and require little or no upkeep.

Quality Certification of Welded Steel Gratings

The application of Welded Steel Grating

Welded steel gratings are used for many different applications. Some common uses include:

- Flooring:Welded steel gratings are commonly used as flooring for mezzanines, catwalks, walkways, and platforms. The grates allow for water drainage and provide good traction in both dry and wet conditions.

- Stair Treads:Stair treads made from welded steel grating can offer good slip resistance and are often used in industrial and commercial buildings.

- Drain Covers:Welded steel grating can be used as a drain cover to provide good drainage and prevent flooding.

- Fencing:Welded steel grating can be used as a fencing material because it is strong and secure. It can also be used as a decorative element in gardens or other outdoor areas.

- Other:There are many other uses for welded steel grating, such as in sunshades, enclosures, and panels.

FAQs for Welded Steel Gratings

Yes, welded steel gratings come in a variety of sizes and can be custom made to meet your specific project requirements.

Welded steel gratings offer many benefits including high strength, durability, slip resistance, and a variety of aesthetic options.

Welded steel gratings are commonly used in industrial and commercial settings as walkways, mezzanine floors, security cages, and machine guards. They can also be used in residential settings as driveway grates, pool surrounds, and decks.

Welded steel gratings are low maintenance and do not require painting or other treatments. In some cases, they may require occasional cleaning to remove dirt or debris. If you live in an area with high traffic, you may need to have the gratings cleaned more frequently.

Lead times for welded steel gratings vary depending on the size and complexity of the project. In most cases, lead times are between two and four weeks. For custom projects, lead times may be longer. Contact us to discuss your specific project requirements.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397