Introduction

Wire mesh is a versatile material with many different applications in a variety of industries. In this article, we will explore the various shapes of wire mesh, including their unique features and common uses. From square metal mesh to hexagonal wire mesh, you’ll learn everything you need to know about these essential components.

Whether you are a construction professional, a DIY enthusiast, or simply interested in the world of wire mesh, this article has something for you. Discover the many different uses and benefits of each type of wire mesh, and learn how to choose the right one for your next project.

1. What is a wire mesh?

Wire mesh, also known as wire cloth or wire fabric, is a versatile and durable material made by weaving or welding thin, malleable wires into a mesh pattern. It is commonly used in a wide range of applications, including filtration, separation, reinforcement, protection, and decoration.

Wire mesh comes in a variety of materials, including stainless steel, copper, brass, aluminum, and galvanized steel, among others, and can be woven or welded into different mesh sizes, wire diameters, and patterns to meet specific performance requirements.

Wire mesh is constructed by interweaving wires in a pattern, either by a weaving machine or by hand. The most common weaving patterns are plain weave, twill weave, and Dutch weave. In a plain weave, the wires cross over and under each other in a simple, alternating pattern.

In a twill weave, the wires cross over and under each other in a diagonal pattern, creating a diagonal texture. In a Dutch weave, the wires are tightly woven in the warp direction and have a thicker wire diameter in the weft direction, resulting in a tight, dense mesh with a high filtration capacity.

Wire mesh is characterized by its strength, flexibility, durability, and corrosion resistance, making it ideal for applications where high tensile strength, flexibility, and durability are required. It is also resistant to wear and tear, weathering, and chemicals, making it suitable for use in harsh environments.

In addition, wire mesh can be easily fabricated and customized to meet specific requirements, such as size, shape, and mesh count.

Wire mesh is used in a variety of applications across many industries. In the construction industry, it is used as reinforcement in concrete structures, such as floors, walls, and bridges. In the automotive industry, it is used as a filter in fuel and oil systems.

In the food industry, it is used as a sieve or filter in processing and packaging applications. In the agricultural industry, it is used as fencing, cages, and screens. It is also used in the aerospace, electronics, and medical industries, among others.

2. Different shapes of wire mesh

Wire mesh comes in a variety of shapes and sizes, each with its unique features and benefits. Here is an in-depth explanation of some of the most common shapes of wire mesh, and their respective features:

Square metal mesh

Square metal mesh, also known as plain weave mesh, is the most basic and commonly used wire mesh pattern. It consists of wires that are woven in a simple over-under pattern, creating a square-shaped mesh.

Square metal mesh is known for its high strength and durability, making it ideal for use in applications that require high tensile strength and corrosion resistance. It is also easily fabricated and can be customized to meet specific size and shape requirements.

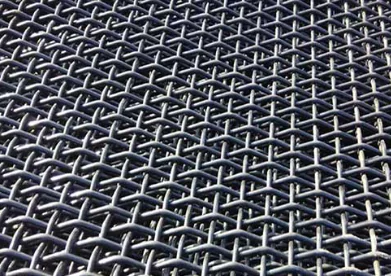

Crimped wire mesh:

Crimped wire mesh is a type of woven wire mesh that has a wave-like pattern. The wires are crimped, or bent, in a zigzag pattern, which creates a textured surface. Crimped wire mesh is often used for decorative purposes, but it also has functional benefits, such as increased stability and support.

It is commonly used in applications such as mining, construction, and agriculture, where it provides reinforcement and protection.

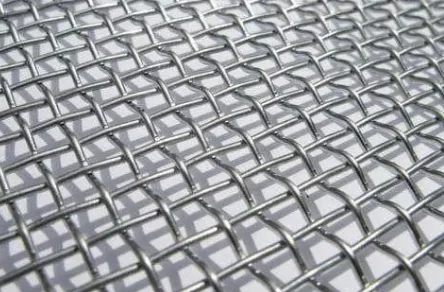

Dutch weave is woven wire mesh

Dutch weave woven wire mesh is a type of wire mesh that has a tight weave and high filtration capacity. It is made by weaving two wires together in an over-under pattern, with the weft wire being larger in diameter than the warp wire.

This creates a tight mesh with a small opening size, which makes it ideal for applications that require high filtration capacities, such as oil and gas filtration, water filtration, and chemical processing.

Hexagonal metal mesh

Hexagonal metal mesh, also known as chicken wire or poultry netting, is a type of wire mesh that has a hexagonal shape. It is commonly used in agricultural applications, such as fencing and animal enclosures. Hexagonal metal mesh is known for its flexibility and ease of installation, making it ideal for use in applications that require quick and easy installation.

Wire mesh comes in various shapes and sizes, each with its unique features and benefits. Square metal mesh is known for its strength and durability, crimped wire mesh provides increased stability and support,

Dutch weave woven wire mesh has a tight weave and high filtration capacity, and hexagonal metal mesh is flexible and easy to install. Understanding the different shapes and features of wire mesh can help you choose the right type for your specific application.

Conclusion

Wire mesh is an important material that plays a vital role in many different industries. By exploring the various shapes of wire mesh, you can gain a better understanding of this versatile material and its many applications. Whether you are a professional or a hobbyist, this article has something to offer everyone.