Introduction

Stainless steel grating is a metal grate that is made out of stainless steel. It has many advantages over other materials such as aluminum, galvanized steel, and carbon steel.

Stainless steel grating can be used in a variety of applications, including walkways, platforms, stair treads, and drainage systems.

It is also corrosion-resistant and can withstand heavy loads. Let’s take a closer look at some of the advantages of stainless steel grating.

What Are The Stainless Steel Gratings?

Stainless Steel Bar Grating are made of stainless steel and come in several different styles. Its durability, resistance to corrosion, and non-skid surface make it an ideal choice for a variety of applications.

Read on to learn more about the different types of stainless steel gratings.

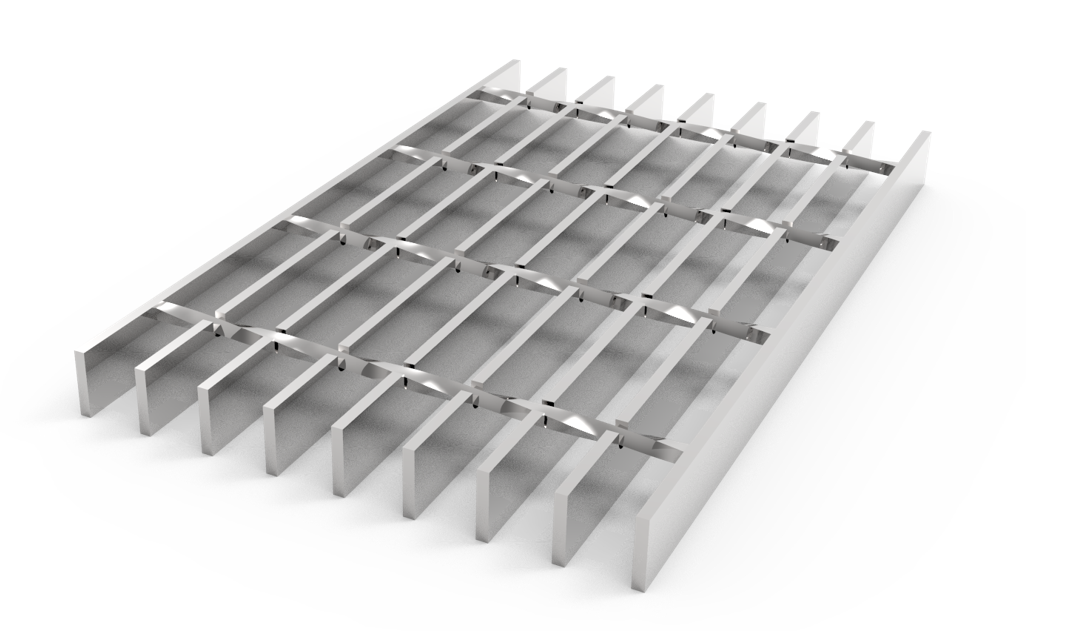

The two most popular styles are welded and swaged. Welded gratings are made by welding the bearing bars and cross bars together to form a grid.

Swaged gratings are made by swaging, or pressing, the bearing bars, and cross bars together to form a grid.

The Advantages Of Using Stainless Steel Bar Grating!

Here are some of the advantages of using stainless steel grating:

1. Corrosion-Resistant:

Stainless steel bar grating is highly resistant to corrosion, and it will not rust. This makes it an ideal material for outdoor applications or environments where there is a lot of moisture.

2. Low Maintenance:

Stainless steel bar grating is very easy to clean, and it does not require a lot of maintenance. This makes it ideal for use in areas where hygiene is important, such as food processing plants.

3. Non-Slip:

The surface of stainless steel bar grating is very smooth, which makes it slip-resistant. This is a great safety feature for walkways, stairs, and other areas where people are walking.

4. Durable:

Stainless steel grating is very strong and durable. It can withstand heavy loads, and it is not susceptible to damage from impact. This makes it an ideal material for applications where there is a lot of foot traffic or heavy equipment.

5. Attractive:

Stainless steel grating has a bright, shiny finish that is very attractive. This makes it an ideal material for use in architectural applications. So, if you are looking for an attractive material for your next project, stainless steel grating may be the perfect choice.

6. Cost-Effective:

Stainless steel grating is very cost-effective. It is a very affordable material that is also very durable. This makes it a great choice for both commercial and industrial applications.

How To Install Stainless Steel Grating?

Here are some of the steps to install stainless steel grating:

1. Measure:

You will need to measure the area where you want to install the grating. Once you have the measurements, you can purchase the grating that you need. It is important to buy the grating that is the correct size for your installation.

2. Cut:

If you need to, you can cut the grating to fit the area that you measured. You will need to use a saw to cut the grating. This is a very easy process, and it only takes a few minutes.

3. Install The Supports:

The next step is to install the supports. The supports can be either floor or ceiling mounted. If you are installing the grating on a floor, you will need to use floor supports. If you are installing the grating on a ceiling, you will need to use ceiling supports.

4. Attach The Grating:

The next step is to attach the grating to the supports. You will need to use bolts to attach the grating. The bolts should be placed at the intersections of the bearing bars and cross bars.

5. Finish Up:

Once the grating is attached, you can finish up the installation by adding any trim or edging that you need. This is a very easy process, and it only takes a few minutes. So, there you have it. Those are the five steps to install stainless steel grating.

The Different Types Of Stainless Steel Grating Products

There are several different types of stainless steel grating products. Below, we will look at the most popular types of products.

1. Welded Grating:

Welded gratings are made by welding the bearing bars and cross bars together to form a grid. This type of grating is very strong, and it is perfect for applications where there is a lot of foot traffic or heavy equipment.

2. Press-Locked Grating:

Press-locked gratings are made by pressing the bearing bars and cross bars together to form a grid. So, the bearing bars and cross bars are locked together.

3. Swaged Grating:

Swaged gratings are made by swaging the bearing bars and cross bars together to form a grid. If you are looking for a grating that is very strong, then this is the type of grating that you need.

4. Aluminum Grating:

Aluminum gratings are made by welding the bearing bars and cross bars together to form a grid. However, the bearing bars and cross bars are made from aluminum. This type of grating is very lightweight.

5. Fiberglass Grating:

Fiberglass gratings are made by welding the bearing bars and cross bars together to form a grid. However, the bearing bars and cross bars are made from fiberglass.

So, this type of grating is very lightweight, and it is perfect for applications where there is a lot of foot traffic.

Applications For Stainless Steel Grating!

There are many different applications for stainless steel grating. Each type of grating has its own unique advantages.

It is important to choose the type of grating that is best suited for your application. Here are some of the most popular applications for stainless steel grating.

1. Commercial And Industrial Flooring:

The most popular application for stainless steel grating is commercial and industrial flooring. The gratings are often used in factories, warehouses, and another type of industrial buildings.

2. Walkways And Catwalks:

Another popular application for stainless steel grating is walkways and catwalks. The gratings are often used in construction projects, such as bridges and buildings.

It is also used in many other types of projects, such as parking garages, power plants, and factories.

3. Mezzanines:

Mezzanines are another type of application for stainless steel grating. The gratings are often used in warehouses and other types of industrial buildings.

So, if you need a grating for a mezzanine, then this is the type of grating that you need.

4. Trench Covers:

Trench covers are another popular application for stainless steel grating. The gratings are often used in construction projects, such as sewers and drainage systems.

Also, the gratings are used in many other types of projects, such as parking garages and factories.

5. Stair Treads:

Stair treads are another type of application for stainless steel grating. However, the gratings are not only used in staircases.

Before choosing a grating for your stair tread, it is important to consult with a professional to see if the grating is rated for the application.

6. Railings:

Railings are another popular application for stainless steel grating. The gratings are often used in commercial and industrial buildings. If you need a grating for a railing, then this is the type of grating that you need.

7. Architectural Panels:

Architectural panels are another popular application for stainless steel grating. This also includes wall cladding. If you need a grating for an architectural panel or wall cladding, then this is the type of grating that you need.

FAQs About Stainless Steel Grating!

Q: What Is Stainless Steel Grating?

A: Stainless steel grating is a type of grating that is made from stainless steel. There are many different types of stainless steel gratings, such as welded gratings, swaged gratings, and aluminum gratings.

Q: What Are The Advantages Of Stainless Steel Grating?

A: The advantages of stainless steel grating include its durability, slip resistance, and safety. Stainless steel grating is also very low maintenance, and it is easy to clean.

Q: What Are The Applications For Stainless Steel Grating?

A: Some of the most popular applications for stainless steel grating include commercial and industrial flooring, walkways and catwalks, mezzanines, trench covers, stair treads, railings, and architectural panels.

Q: What Is The Most Popular Type Of Stainless Steel Grating?

A: The most popular type of stainless steel grating is welded grating. Welded gratings are made by welding stainless steel bars to a steel frame.

Q: What Are The Dimensions Of Stainless Steel Grating?

A: The dimensions of stainless steel grating vary depending on the type of grating. For example, welded gratings typically have bar thicknesses of 1/8″ or 3/16″ and bar spacing of 1″ or 2″. Swaged gratings typically have bar thicknesses of 1/4″, 3/8″, or 1/2″ and bar spacing of 2″ or 4″.

Conclusion

Galvanized steel grating is a popular choice for many applications because of its benefits. It offers strength, durability, and corrosion resistance, making it the perfect option for a variety of settings.

If you are looking for a product that can provide all of these benefits and more, galvanized steel grating may be the ideal solution for you.

Contact chinagratings.com today to learn more about our products and how we can help you find the perfect fit for your needs.