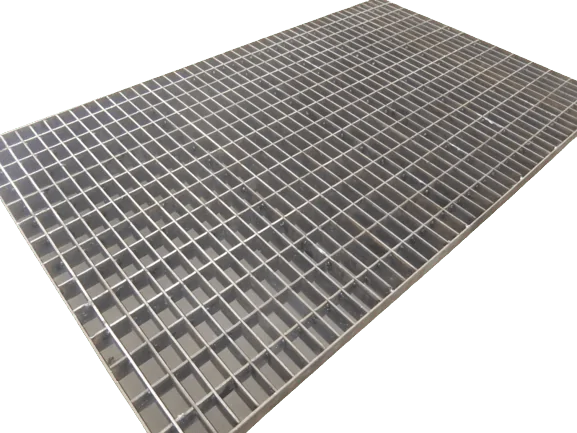

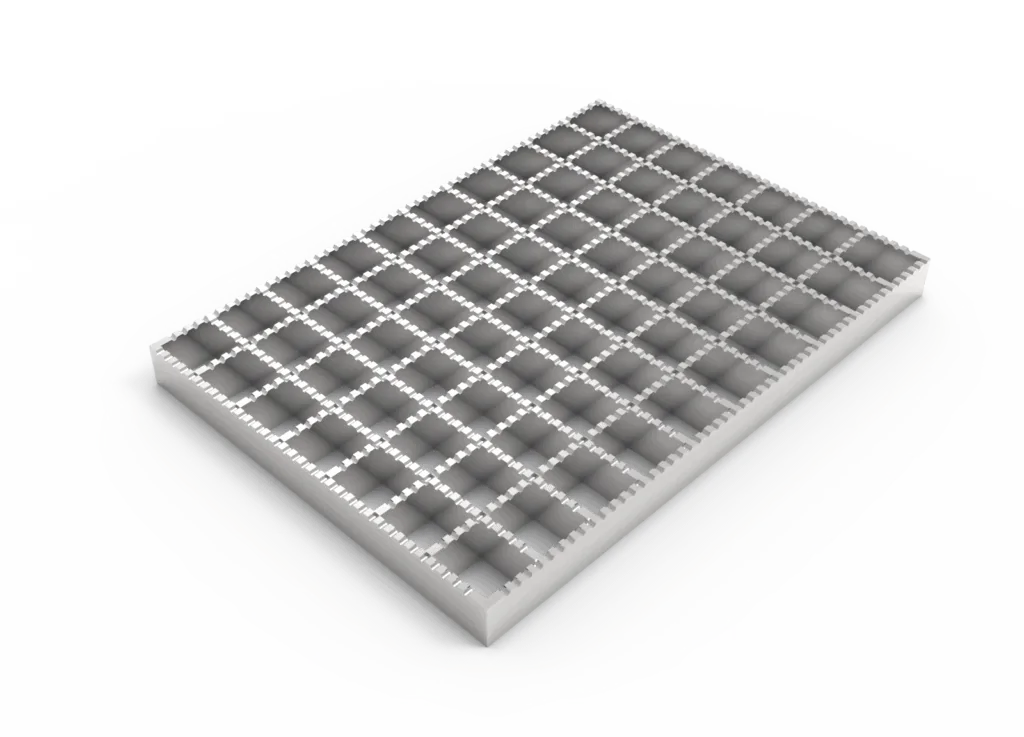

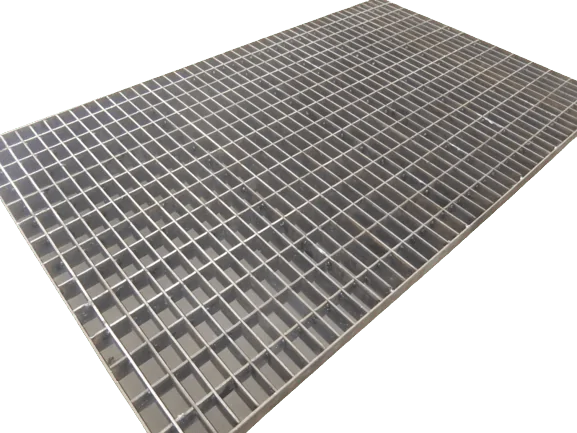

General Introduction To Press-locked Steel Grating: All You Need To Know

- Superior quality press-locked steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

Perforated Metal

General Introduction To Perforated Metal

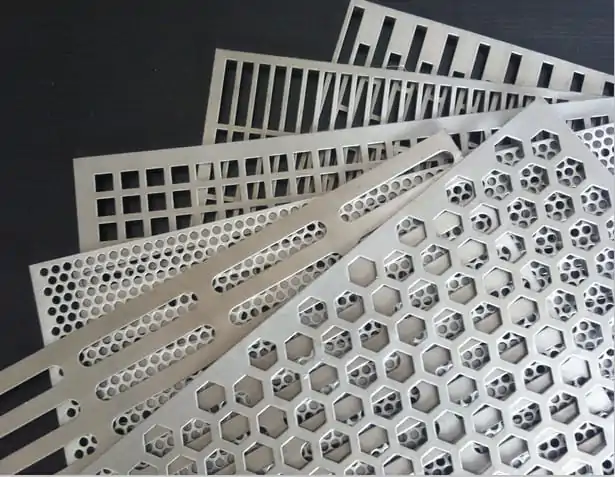

Types of Perforated Metal

Perforated metal is a versatile material that is widely used in various industries and applications due to its unique perforation patterns and functionality. Here are some common types of perforated metal:

Round Hole Perforated Metal

Round hole perforated metal is the most common and widely available type of perforated metal. It features evenly spaced round holes throughout the sheet, offering a high open area and good airflow. This type is suitable for applications such as screens, filters, ventilation panels, and decorative elements.

Square Hole Perforated Metal

Square hole perforated metal is characterized by evenly spaced square-shaped holes. It provides a distinct appearance and offers greater strength compared to round hole perforated metal. Square hole patterns are often used in architectural designs, fencing, machine guards, and speaker grilles.

Hexagonal Hole Perforated Metal

Hexagonal hole perforated metal features hexagon-shaped holes arranged in a regular pattern. This type offers a unique aesthetic appeal and is suitable for applications where increased open area, strength, and visual interest are required. Hexagonal hole perforated metal is often used in decorative panels, guards, and facade elements

Decorative Perforated Metal

Decorative perforated metal combines functionality with aesthetics, featuring custom-designed perforation patterns. It offers endless design possibilities, allowing for intricate shapes, logos, and images. Decorative perforated metal is commonly used in architectural facades, signage, interior design elements, and artistic installations.

Micro Perforated Metal

Micro perforated metal is characterized by extremely small holes that are closely spaced. These tiny holes provide excellent acoustic performance, making it ideal for speaker grilles, sound absorption panels, and architectural applications requiring noise control. Micro perforated metal offers both functionality and an aesthetically pleasing appearance.

Embossed Perforated Metal

Embossed perforated metal combines perforations with raised patterns or textures on the surface. This type adds visual interest and can be used for decorative purposes or to enhance grip and slip resistance. Embossed perforated metal is commonly employed in flooring, stair treads, walkways, and architectural features.

Slotted Perforated Metal

Slotted perforated metal consists of elongated slots instead of round or square holes. The slots can be straight or staggered, offering design flexibility and enhanced visual appeal. This type of perforated metal is commonly used in architectural applications, sunshades, partitions, and equipment enclosures.

Perforated Metal Specifications

| Specification | Description |

|---|---|

| Material | Stainless steel, carbon steel, aluminum, galvanized steel, etc. |

| Thickness | Ranges from 0.2mm to 12mm (depending on material and application) |

| Hole Shape | Round, square, slotted, hexagonal, custom designs, etc. |

| Hole Diameter | Varies based on the hole shape and application requirements |

| Open Area | Percentage of open area in the perforated metal sheet |

| Sheet Size | Standard sizes: 4' x 8', 4' x 10', and custom sizes available |

| Perforation Pattern | Regular or custom-designed patterns |

| Pitch | Distance between the centers of adjacent holes |

| Margins | Unperforated borders or margins around the sheet |

| Finish | Mill finish, powder-coated, painted, anodized, or custom finishes |

| Flatness | Flat or may have a slight curvature depending on the material and thickness |

| Tolerance | Permissible dimensional deviations from the specified measurements |

| Application | Various industries such as architecture, automotive, manufacturing, etc. |

The application of Perforated Metal

Perforated metal is a versatile material that finds a wide range of applications across various industries. Its unique perforation patterns and functional characteristics make it suitable for numerous purposes. Here are some common applications of perforated metal:

Architectural and Construction:

- Facades and Cladding: Perforated metal panels are used in building facades and cladding to provide an attractive aesthetic, ventilation, and sunshade capabilities.

- Balustrades and Railings: Perforated metal sheets are employed in balustrades and railings to ensure safety while adding a modern and stylish look to architectural structures.

- Screens and Partitions: Perforated metal screens and partitions are used for interior design, creating separations while allowing light and airflow.

Filtration and Separation:

- Air and Gas Filtration: Perforated metal is utilized in air and gas filtration systems, ensuring the removal of contaminants while maintaining proper airflow.

- Water and Liquid Filtration: Perforated metal screens are used in water and liquid filtration applications, separating solids and impurities from the fluid.

Automotive and Transportation:

- Grilles and Vents: Perforated metal sheets are commonly used as grilles and vents in automotive applications, providing airflow while protecting against debris and insects.

- Noise Control: Perforated metal panels with sound-absorbing materials are used to reduce noise in automotive and transportation applications.

Industrial Equipment and Machinery:

- Machine Guards: Perforated metal sheets are employed as machine guards to protect operators from moving parts while allowing visibility and ventilation.

- Conveyor Systems: Perforated metal is used in conveyor systems to facilitate drainage and airflow, ensuring efficient material handling.

Energy and Utilities:

- Solar Panels: Perforated metal sheets are used as support structures for solar panels, ensuring stability and airflow for optimal energy production.

- Heat Exchangers: Perforated metal is employed in heat exchangers to enhance heat transfer efficiency and promote airflow.

Furniture and Decorative Applications:

- Furniture Design: Perforated metal is utilized in furniture design, including chairs, tables, and shelving units, adding a unique and modern touch.

- Lighting Fixtures: Perforated metal shades and diffusers are used in lighting fixtures, creating interesting light patterns and enhancing aesthetics.

Acoustic Solutions:

- Speaker Grilles: Perforated metal is commonly used as speaker grilles, providing protection while allowing sound to pass through.

- Acoustic Panels: Perforated metal sheets with sound-absorbing materials are employed in acoustic panels and barriers to control noise levels.

FAQs for Perforated Metal

Perforated metal is a sheet of material, typically metal, that contains a pattern of regularly spaced holes. These holes can be of various shapes, such as round, square, or slotted, and are created through a punching or drilling process. Perforated metal offers a range of functional and aesthetic benefits for different applications.

Perforated metal offers several advantages:

- Improved airflow and ventilation: The presence of holes allows air, light, and sound to pass through while maintaining structural integrity.

- Enhanced visibility: Perforated metal can provide visibility through screens and partitions without sacrificing privacy or security.

- Efficient filtration and separation: The holes in perforated metal facilitate filtration of liquids, gases, and solids in various industrial processes.

- Aesthetic appeal: Perforated metal can be used as a decorative element, adding texture, pattern, and visual interest to architectural designs.

- Structural strength: Despite having holes, perforated metal retains its strength and durability, making it suitable for applications that require both form and function.

Perforated metal can be made from a variety of materials, including stainless steel, carbon steel, aluminum, brass, copper, and galvanized steel. The choice of material depends on factors such as corrosion resistance, strength requirements, aesthetic considerations, and the specific application.

Perforated metal finds numerous applications in architecture, such as:

- Facades and cladding: It provides an aesthetically pleasing appearance while offering ventilation and sunshade capabilities.

- Interior design: Perforated metal can be used for decorative elements, room dividers, and acoustic panels, adding texture and visual interest to spaces.

- Balustrades and railings: It can be utilized as infill panels in balustrades and railings, combining safety and design.

Yes, perforated metal can be customized to meet specific requirements. The hole size, shape, pattern, open area, material, and finish can be tailored based on the application needs. Customization options allow for precise functionality, aesthetic enhancements, and compatibility with different environments.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397