Introduction

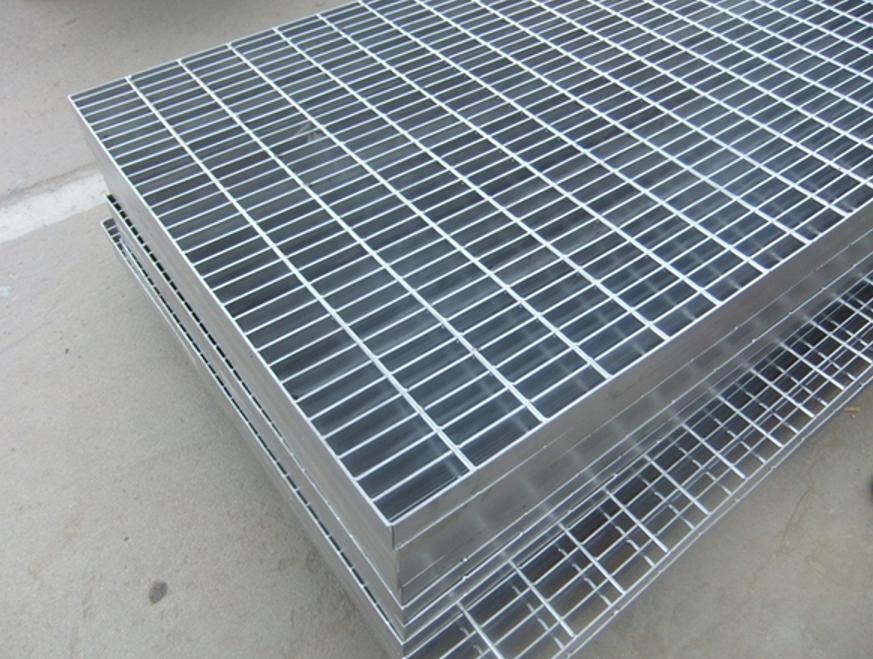

Steel gratings are an important part of many industrial and commercial facilities.

They provide a strong, sturdy surface that can be used for a variety of purposes.

However, with so many different types and styles of steel gratings available on the market today, it can be difficult to know which type is right for your specific application.

In this comprehensive guide, we will discuss everything you need to know about choosing steel gratings!

In this blog post, we will outline the different types of steel gratings and help you choose the right one for your project.

How To Choose Different Kinds Of Steel Gratings?

First, identify the material of the steel grating. Then, identify the surface treatment of the steel grating. Finally, choose the right size and shape of steel grating. Following these steps can help you choose the right steel grating for your needs.

With so many options on the market today, it is important to select the right grate for your needs. Let’s get started!

Top 7 Ways To Choose Different Kinds Of Steel Gratings!

1. Type Of Steel of the steel gratings:

The first step in choosing the right steel grating is to select the type of steel. There are three common types of steel gratings:

1. Carbon steel gratings are the most economical option. They are best suited for applications that do not require corrosion resistance or special finishes.

It is important to note that carbon steel gratings will rust if exposed to moisture. You can protect them from corrosion by painting or hot-dip galvanizing.

Benefits

– Inexpensive

– Lightweight

– Good strength and durability

– It- Easy to install

2. Stainless steel gratings are more expensive than carbon steel, but they offer superior corrosion resistance.

In addition, they are available in a wide range of finishes, including brushed and mirror. Thus, stainless steel gratings are often used in architectural and food processing applications.

Benefits

– Corrosion resistant

– Available in a variety of finishes

– Good strength and durability

3. Aluminum gratings are lightweight and offer excellent corrosion resistance, but they are more expensive than steel gratings.

On the plus side, they are non-sparking and can be used in applications where flammability is a concern.

Benefits

– Lightweight

– Corrosion resistant

– Non-sparking

– Superb strength-to-weight ratio

When deciding on the type of steel, it is important to consider the environment in which the grating will be used.

If the grating will be exposed to corrosive materials or weather conditions, stainless steel or aluminum gratings are the best options.

If price is the primary concern, carbon steel gratings are the best choice.

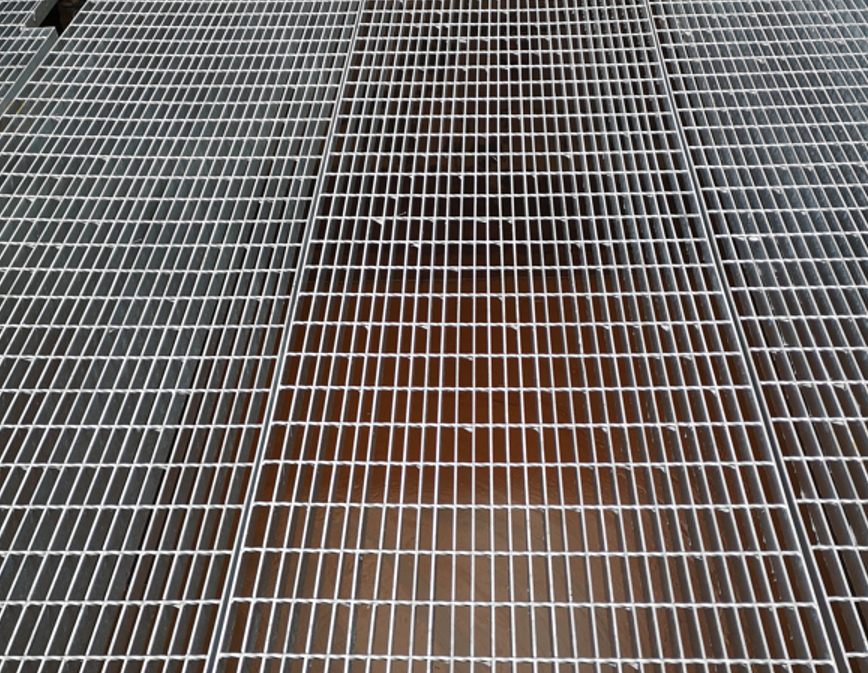

2. Mesh Size of steel gratings:

Mesh size is an important consideration when choosing steel gratings. Smaller meshes are best suited for applications that require a high level of trappings, such as food processing or waste management.

Larger meshes are better for applications that require good drainages, such as stormwater drains or outdoor walkways.

The right mesh size will depend on the specific application. For example, if you are looking for steel gratings for a storm water drain, you will want to choose a grating with a large mesh size.

This will allow water to flow through quickly and prevent clogging. A small mesh size, on the other hand, would be more appropriate for a food processing application.

It is important to select the right mesh size for your needs to ensure optimal performance.

3. Load Capacity of steel gratings:

The load capacity of steel gratings is an important consideration. Light-duty gratings are best suited for applications that do not require heavy loads, such as walkways or mezzanines.

Heavy-duty gratings are necessary for applications that will bear heavy loads, such as vehicle traffic or industrial machinery.

It is important to select the bar grating with the appropriate load capacity for your application. In many cases, the load capacity will be determined by the type of steel used.

For example, aluminum bar grating are typically not as strong as steel gratings and are not suitable for heavy-duty applications.

During the selection process, it is important to consider the maximum load that the grating will need to support. This will ensure that the steel grating you select is up to the task.

You can find the load capacity rating for each steel grating on our website.

4. Environments of bar grating:

If the steel grating will be used outdoors, it is important to select one that is designed for outdoor use. Outdoor steel gratings are typically made of stainless steel or aluminum to resist corrosion.

They may also have a special finish, such as a powder coat, to further protect against the elements. Indoor steel gratings are not subject to the same environmental concerns and can be made of any type of steel.

Both indoor and outdoor bar grating can be custom-designed to meet the specific needs of your application.

It is important to consider the environments in which the steel grating will be used when making your selection.

Any bar grating that will be used outdoors should be designed for outdoor use to ensure optimum performance. When used indoors, steel gratings can be made of any type of steel.

You can find steel gratings for both indoor and outdoor use on our website.

5. Finish of steel gratings:

Steel gratings are available in a variety of finishes, from plain to hot-dipped galvanized. The type of finish you select will depend on the environment in which the grating will be used.

For example, hot-dipped galvanized bar grating are best suited for outdoor applications In such cases, the steel grating will be exposed to moisture and humidity, which can cause corrosion.

A hot-dipped galvanized finish will provide a layer of protection against these elements. If the steel grating will be used indoors, a plain finish is typically sufficient. Indoor steel gratings are not subject to the same environmental concerns as outdoor steel gratings.

A plain finish is also less expensive than a hot-dipped galvanized finish. Econo-Grate steel gratings are available with either a plain or hot-dipped galvanized finish.

You can select the finish that is best suited for your application when ordering. Whenever possible, it is best to select a steel grating with a finish that is appropriate for the environment in which it will be used.

6. The Material Of Steel Gratings

The material of bar grating is an important consideration. Steel gratings are available in a variety of materials, including aluminum, steel, and stainless steel. Each material has its advantages and disadvantages.

For example, aluminum gratings are lightweight and corrosion-resistant, but not as strong as steel gratings. Steel gratings are strong and durable, but may rust if exposed to moisture.

Stainless bar grating are strong and corrosion-resistant, but more expensive than other options.

When selecting the material for your steel grating, it is important to consider the environment in which it will be used.

Aluminum gratings are a good choice for outdoor applications, steel gratings are a good choice for indoor applications, and stainless steel gratings are a good choice for applications where corrosion resistance is a concern.

The materials for steel gratings are selected based on the application. Sometimes steel gratings are made of aluminum to avoid corrosion in a certain environment.

Steel gratings can also be made of steel or stainless steel depending on the needs. If steel gratings will be used in an area where there is a concern for corrosion, stainless steel should be used.

7. The Surface Protection Of Steel Gratings

When bar grating are used in an outdoor environment, they are often exposed to moisture and humidity, which can cause corrosion. To protect against this, steel gratings are available with a variety of surface treatments, such as hot-dip galvanizing.

Hot-dip galvanizing is a process in which the steel grating is dipped in a vat of molten zinc. This creates a layer of protection against corrosion. Heavy duty Steel gratings can also be powder-coated. Powder coating is a process in which a powder is applied to the steel grating and then baked on.

This creates a durable, long-lasting finish. Steel gratings can also be painted. Painting provides a layer of protection against corrosion but is not as durable as hot-dip galvanizing or powder coating.

When selecting heavy dutybar grating for an outdoor application, it is important to choose a grating with a surface treatment that is appropriate for the environment.

Hot-dip galvanizing and powder coating are good choices for outdoor steel gratings.

8.FAQs about how to choose steel gratings

Q:How to choose the right grating?

A:There are many factors that need to be considered when choosing the right grating.

The first thing you need to do is determine what kind of environment the grating will be used in.

Will it be used indoors or outdoors? Will it be exposed to harsh chemicals or other corrosive materials?

Once you have a good idea of the environment the grating will be used in, you can narrow down your choices.

Q:How to choose the right material?

A:The next thing you need to consider is what kind of material the grating will be made from.

There are many different types of steel gratings, each with its own advantages and disadvantages.

For example, galvanized steel gratings are resistant to corrosion and are often used in outdoor applications.

Stainless steel gratings are often used in food processing facilities because they are easy to clean and maintain.

Conclusion

When it comes to choosing the right bar grating for your specific needs, it can be a daunting task.

With all of the different types and sizes available on the market, how do you know which one is right for you? The best way to make this decision is by considering what you need the grating to do.

Not sure where to start? Our team at chinagratings would be happy to help you out.

We have years of experience in the industry and can recommend the perfect steel grate for your needs. Give us a call today!