Introduction

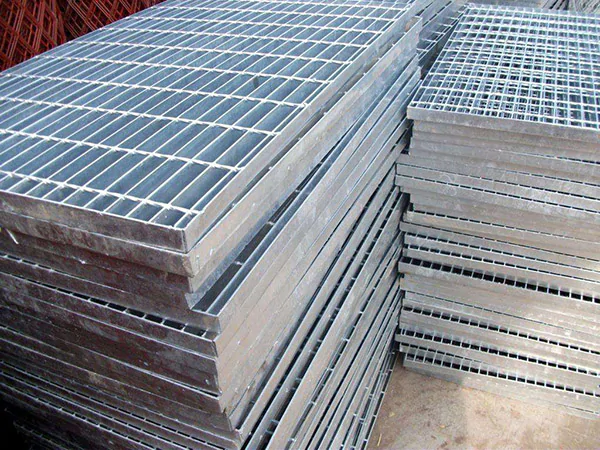

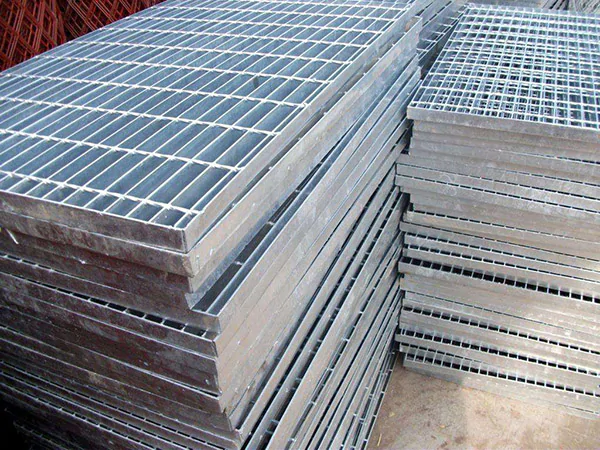

Do you know the distinction between manually and mechanically press-welded steel gratings? Do you wish to learn about each of their advantages and benefits? We’ll explain the distinctions between the two varieties of processing steel gratings in this article.

For hand-welded steel gratings, workers first punch in the bearing bars, make them stand upright, and place the cross bars in the holes they drill.

For machine-press-welded steel gratings, workers use the hydraulic resistance welding automatic pressure welding machine.

Do you want to know more regarding the comparisons between hand-welded and machine-press-welded steel gratings? Continue reading.

What is a Hand-Welded Steel Grating?

Hand-welded is the process where workers do the steel grating manually in hand. The workers make the bearing bars stand upright to be punched and put the cross bars in the holes in it. By the way of spot welding, the cross bars and the bearing bars are integrated.

Hand-welding steel gratings are accomplished by inserting hollow tube cross bars into pre-punched holes in bearing bars. The cross bars are then hydraulically pushed together to provide a solid mechanical connection.

The cross bars are hidden beneath the upper surface of the bearing bars, giving the bearing bars a consistent and appealing architectural appearance.

The procedure of hand welding is incredibly effective and customizable. The cross bars can fit in after the steel has been reduced to size and the bearing bars have been punched in. They then assembled it after properly fitting the steel bar metal grating. All necessary finishing touches are applied by the welders to guarantee that the gratings meet the standards and the client’s particular specifications.

What is a Machine-Press-Welded Steel Grating?

Machine-press-welded is the process where the machine itself is programmed in making the steel grating. In using the welding machine which has the feature of hydraulic resistance, steel grating can be created in no time.

The manipulator will automatically put the cross bars on the bearing bars aligned evenly, and press the formal ones into the latter ones by welding power and liquid pressure. So that you can get high-quality stainless steel gratings with solid joints, stability, and great strength.

When it comes to mass production, this way of processing steel plate grating can save costs.

Heavy-duty steel grating that has been hand-welded offers design flexibility and a speedy manufacturing process, allowing the products to reach construction sites more quickly. It has high-production robotics and huge-capacity hydraulic presses with automated feed lines.

It keeps a competitive edge in the steel grating business by adopting robotic technologies. The precise, cost-effective high-capacity hydraulic presses provide users with durable, heavy-duty steel grating solutions.

The Benefit of two Types of Steel Gratings

Here are the benefits of the two types of steel gratings:

High load capacity and strength

Steel is a more robust and long-lasting substance. Greater weight and pressure won’t cause it to shatter. Steel grating outperforms other materials in terms of strength. Greater impact resistance in the steel grating enables it to support higher weights.

Since the steel drainage grille is more able to withstand high temperatures, it is also being tried in locations with sizable freezer compartments or facilities in hot climates.

Slip-resistant surface

Serrations can be added to increase the anti-slip effectiveness according to the various uses.

Corrosion protection

Its corrosion resistance and durability have significantly increased thanks to the hot-dip galvanized coating, and it is simple to maintain in practical applications.

Good drainage performance

The hygienic aspect of employing steel grating is a major benefit. Steel is smooth and easy to clean, and trash won’t get caught in ridges or holes because of this. Steel is a material that can also withstand the development of germs and other potentially dangerous impurities.

Steel gratings are now the preferred option for establishments including hospitals and food service facilities, such as restaurants, commercial kitchens, and food processing plants.

Simple to install and keep up

They don’t need to be changed frequently. Additionally, cleaning it doesn’t require much effort, so you may save money in this way as well. Overall, steel gratings are a more economical option in every way.

Forge welding rectangular bearing bars and drawn cross bars produces welded wire metal grating. Years of operation under the toughest conditions are possible because of this welding technology’s positive, fused connection.

Choice to safety

There are fewer lips that people could trip over because of the steel metal floor grating’s narrow profile. Additionally, the slot is thinner, making it less likely to jam and harm someone for having exceptionally sturdy metals and a safety metal grating.

Aesthetically appealing appearance

The steel grating’s visual appeal is yet another outstanding advantage just like in a woven wire metal grating. It gives your cover a more stylish and contemporary design theme. The steel grating is more attractive and complements any design effectively.

Therefore, wherever you decide to place the trench drain, the grating will blend in perfectly and appear to always be a part of the design.

A Detailed Comparison: Hand-Welded VS Machine-Press-Welded

Machine-press-welded steel gratings intend to have an attractive appearance over hand-welded steel gratings since the machine-press-welded go through the same process, leaving little differences between them.

Hand-welded steel gratings are more convenient for operation. If the actual pressure required is beyond the limit of the machine or the size and other specifications of a product client needs are beyond what a machine can produce, operators need to integrate them after the machine-making process. In that case, the way of hand-welded seems more convenient for the market.

For processing irregular steel gratings, hand-welding makes it possible to directly put cross bars in the place where they want. But it’s not easy for the machine-press-welding method due to the inconvenience to adjust their setup. So in this way, hand making indeed saves the cost.

The machine-press-welded method is affected by equipment and current and voltage. And the process is related to the depth of raw bearing bars for the large width differences between them may decrease the welding strength and make it inconsistent.

So the defect lies in that the welding cannot be fully guaranteed, which may result in the failures of cross bar welded into bearing bars so that it would be a welded metal grating.

And due to the rated capacity of the machine, heavy-duty steel gratings with large sections can not be produced, only achieved by manual welding.

There will be gaps between the bars, and it is not that possible to weld every contact point, so the hand-welded steel grating may not be strong enough for certain requirements.

Compared with the machine-press-welded one, it may lack in its strength. But the advantage is that it can deal with complex types of steel gratings as the customer want.

To maximize production and efficiency, use automation. Commercial steel grate welding can be completed entirely by the robotic welder or the machine-pressed welding machine. As a result, staging materials will take less time, and fewer workers will be required.

The robotic welder places all of the material into the fixture and then welds it there, eliminating the need for two separate areas to be used for fitting and welding.

Other Considerations When Choosing Processing Types

When you’re looking for steel gratings whether it is hand-welded or machine-press-welded, here are some considerations to look out for:

Mode of Production

It should be a welded steel grating that is fixed by pressure resistance welding at each point where the bearing bar and cross bar cross. Typically, square steel or twisted steel is used for the crossbar. It should have a strong framework, high strength, and large carrying capacity because it serves as floors, stair treads, fences, and walkways.

It should be a steel grate that is fastened by applying pressure to the crossbar so that it becomes pre-open flat steel at each point where the bearing bar and crossbar intersect just like in a compound metal grating.

The cross bar is typically flat steel. Both an appealing appearance and a reliable connection should be offered because it is can be used for floors, platforms, fences, trench coverings, stair treads, and other purposes in industries, civic, and commercial buildings.

Materials

The intended purpose of a compound metal grating must be taken into account while selecting the materials. Is it simply employed to grate walkways? Or a drainage system? Does the gating have to be passed through by the vehicles?

In these situations, you must make sure that the grating is strong enough to ensure that the right materials were chosen.

Each type of material has special qualities and uses. Here, we’d like to give you a brief overview of it to aid in your material selection.

Galvanized steel – it is affordable, strong, and suitable for platforms and walkways in petrochemical, electricity, and municipal engineering, among other industries. Low carbon steel – it is ideal for municipal buildings, interior decoration, building materials, platform aisles, and stamping because of its excellent ductility.

304 stainless steel – it has excellent heat and corrosion resistance, high tensile strength, and is suitable for high-temperature operations in chemical, food, and power facilities as well as wastewater treatment and other applications.

316 stainless steel – it is for chemical, pulping, and paper processing, textile equipment, petroleum refining, etc.

Aluminum – it is widely used in interior ceilings, outdoor curtain walls, other aesthetic applications, and mechanical equipment maintenance platforms because of its lightweight, excellent corrosion resistance, and attractive look.

Which Mesh Size to Choose

Welded steel gratings typically have mesh sizes of 33 mm by 33 mm and 34 mm by 38 mm. There are various ways to divide wire mesh metal grating depending on the different load, place, use, method of application, and customer requirements.

- Load – The load capacity of the grating increases with decreasing wire mesh metal grating size.

- Application – More light may travel through the larger wire mesh. Objects cannot fall off because of the smaller mesh.

- Customer – The optical perception of the grating is influenced by the size and form of the mesh.

Surface Protection

Steel gratings come in black, galvanized, and without any further surface treatment. The most common method used to treat the surface of low-carbon steel gratings is hot-dip galvanizing. It offers a surface that is clear, and smooth and requires little upkeep for floor metal grating.

Additionally, it creates a stable protective barrier with excellent corrosion resistance. Hot galvanizing offers a 40-year corrosion protection warranty. Offer additional protection for specialized applications, such as powder coating or colored painting.

The performance of anti-slip

In general, there are two different surface shapes for grating. One is serrated, while the other is smooth. To improve the anti-slip performance, we typically serrate the grating surface.

Carrying capacity

There are various carrying capacities for steel gratings. Steel gratings with tiny pitches often have a high carrying capacity, while those with big pitches typically have a low carrying capacity. According to the needs of our project, we will select the appropriate carrying capacity.

Process Flow and Duration Estimation

Carbon steel, galvanized steel, or stainless steel are all acceptable raw materials for steel gratings. Low-carbon steel is the most popular option since it is affordable and simple to weld.

All the materials must be trimmed to size and thoroughly cleaned to get rid of any dirt, oil, or other pollutants to maintain this process flow. Not to mention, before being approved, the raw material must pass quality control.

The major focus of steel grating edge preparation is trimming and rounding off the benefits of steel grating. Any edges that are rough or sharp and could cut someone should be removed just like in an expanded metal grating.

This also provides the grating with a more polished appearance. Additionally, the edge preparation assists in avoiding rust on the grating.

The steel grating machine is a crucial piece of machinery in the process. It is primarily used to join the bearing bar and cross bar to create a steel grating-like structure. There are numerous different steel grating machines; the most popular ones include CNC machines and automatic welding equipment.

The manufacturing process for steel grating also includes marking. Steel grating is marked primarily to show its size, type, and other pertinent information. The expanded metal gratings are identifiable because of the marking. Additionally, it aids in avoiding the mixing up of the steel grating.

Maintenance Coverage

For steel gratings to remain in good condition just like in perforated metal grating, adequate maintenance is crucial. The most common method for accomplishing this is through routine cleaning and inspection.

The perforated metal grating can easily become dirty or corroded because of its constant exposure to the weather. You may stop this from happening by doing routine cleaning and inspection, especially in an expanded metal grating.

Inspection and Packaging

The final steps in the steel grating production process are inspection and packaging. This is done to ensure that the gratings are in perfect condition and up to code. They are packaged for shipping after they have been inspected. Before being shipped, steel grating and other products, such as trench drain grating, must be examined and packaged.

Conclusion

We believe that these suggestions will enable you to rapidly select the best steel grating processing type if you are seeking steel grating processing types for your projects. Whether it is a hand-welded or machine-press-welded process you choose for your steel gratings, make sure it is suitable for your application and needs.