Do you need help understanding flat bar sizes and their importance in various industrial applications? This could be a looming problem in executing your projects efficiently. We’ve got a solution tailored for such situations. This blog is intended to shed light on the crucial role of flat bar sizes in different industries and how learning about them can bring a pivotal change in your operations.

Grasping the fundamentals of flat bar sizes is paramount in numerous industries, be it construction, manufacturing, automobile, or renovation. Having a clear understanding of different sizes can significantly enhance the precision and efficiency of your work. It can cut down your costs, reduce waste, and contribute substantially to the overall productivity of your operations.

By the end of this piece, we assure you you’ll have a fuller understanding of flat bar sizes and their value. So, please sit back, learn, and let’s revolutionize how your industry works, one flat bar size at a time. Stay tuned, and you’re about to enter a world of industrial wisdom.

1. What Is a Flat Bar?

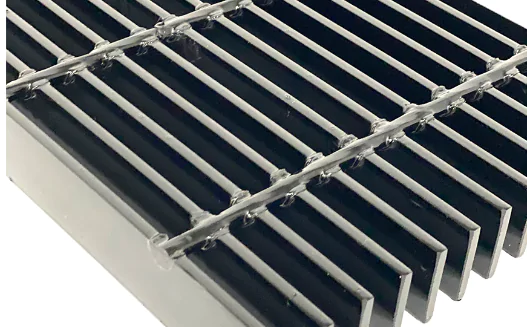

Based on my years of hands-on experience in the business, a Flat Bar Standards Guide is a rectangular bar with one dimension, usually the width, that is much bigger than the other. Most of the time, its thickness is between 1/8 inch and 1/2 inch or more. These bars come in different lengths and widths and can be made of other materials. They are often made to fit the needs of the person or the project.

Flat bars are made to be both strong and rigid, which makes them a good choice for a wide range of industry uses. Because they are flat and have sharp edges, they are easy to weld, cut, and machine. They are also trendy because they last long and are resistant to wear, tear, and rust.

Flat Bar Sizes Chart

| Size (mm) | Size (inches) | Thickness (mm) |

| 25 × 25 | 1″ × 1″ | 2 mm |

| 40 × 40 | 1.1/2″ × 1.1/2″ | 4 mm |

| 50 × 50 | 2″ × 2″ | 4 mm, 5 mm, 6 mm |

| 60 × 60 | 2.1/4″ × 2.1/2″ | 5 mm |

| 75 × 75 | 3 × 3 | 6 mm |

| 80 × 80 | – | 6 mm, 8 mm |

| 20 x 20 | 3/4” x 3/4” | 3mm |

| 25 x 25 | 1” x 1” | 3mm to 6mm |

| 30 x 30 | – | 3mm to 6mm |

| 32 x 32 | 1.1/4” x 1.1/4” | 3mm to 6mm |

| 38 x 38 | 1.1/2” x 1.1/2” | 3mm to 6mm |

| 40 x 40 | – | 3mm to 6mm |

| 50 x 50 | 2” x 2” | 3mm to 6mm |

| 60 x 60 | – | 5mm to 6mm |

| 65 x 65 | 2 1/2” x 2 1/2” | 5mm to 6mm |

| 75 x 75 | 3” x 3” | 5mm to 6mm |

2. Industry Standards for Flat Bars

A. Common Sizes and Measurements Used Globally

From my professional experience, it’s important to know the Industry-Standard Flat Bar Measurements that are used worldwide to ensure that production is consistent and of good quality. Flat bars are usually measured by their width and thickness. They can be as thin as 10mm wide and 2mm thick and as wide as 300mm and 50mm thick. But these aren’t always followed because the size can change depending on how it’s used or what the client wants. Still, most businesses use flat bars that fall within these limits.

In the U.S., flat bars are usually measured in inches, while most of the world uses the metric system. Being familiar with both unit systems is essential because it makes translating measures and doing business across borders easier.

B. Industry Standards and Their Establishment

Establishing Flat Bar Industry Norms was not an overnight endeavor. It took decades of work by manufacturers, engineers, study institutions, and regulatory bodies working together. The main goal was to ensure that output was safe, high-quality, and sustainable.

ASTM International, which used to be called the American Society for Testing and Materials, helped set guidelines for steel products like flat bars. Their method for figuring out the size and quality of these bars has been widely used and is seen as a standard in business.

The European Committee for Standardization (CEN), which sets guidelines for flat bars and other steel products, is a similar group in the European Union. Its rules ensure that steel items in the European Economic Area are safe and of good quality.

C. Differences in Standards Between Countries or Regions

Even though people work together to create global standards, there are still differences. Most of the time, these differences are caused by geography, technology, or economics.

For example, ASTM International and CEN standards are generally accepted, but China and Japan often have different rules. They have their governing bodies, the Standardization Administration of China (SAC) and the Japanese Industrial Standards (JIS), which set different requirements for flat bars for their businesses.

As someone with a lot of experience in the steel business worldwide, it’s important to know about these differences to ensure that international trade goes well and that regional production standards are followed. I’ve learned that giving correct, honest, and dependable information is the best way to keep trust in this fast-changing global steel market.

3. Variations in Flat Bar Sizes

A. Why do Variations in Size Exist?

In my many years of work in the materials business, I’ve worked with different kinds of metals, such as flat bars. Variations in Flat Bar Sizes primarily stem from the diverse requirements of distinct businesses and applications. Manufacturers make these bars in different sizes so that they can meet the needs of each business.

It’s also important to note that the material used affects how these sizes vary. For example, steel, aluminum, and copper have different ways of making flat bars, affecting the range of sizes and the process of standards.

B. How These Variations Affect Their Functionality

The size of a flat bar is a big part of how it can be used. From my observations, the Standard Flat Bar Dimensions dictate its utility, encompassing width, thickness, and length. For example, bigger, thicker flat bars are usually used for structural support in building and construction because they are strong and stable. On the other hand, smaller, thinner flat bars are often used in industries like electronics or precision engineering, where work needs to be delicate and precise.

In the end, the relationship between the size of a flat bar and how it works is the most important thing. Because of this, it’s essential to have a good idea of the flat bar sizes that work best for a given application.

C. Overview of Industries or Applications Where Non-Standard Sizes are Used

Many industries require flat bars in sizes that deviate from the Common Flat Bar Dimensions to cater to unique requirements. For instance, in the aerospace sector, where I’ve worked extensively, bespoke flat bars are frequently utilized to manufacture airplane components, given that airplanes are tailored to meet specific, non-standard criteria.

In automobile manufacturing, numerous parts necessitate flat bars that don’t conform to standard sizes, catering to diverse vehicle models. Ensuring the precise dimensions of these flat bars is pivotal, enhancing vehicle safety and efficiency.

Custom-sized flat bars are also gaining traction in the design and construction, particularly when crafting unconventional structures or architectural elements. This trend underscores the significance of having a variety of flat bar sizes in the contemporary engineering landscape, which is constantly evolving and brimming with innovation.

Having been entrenched in the materials sector for an extended period, I can vouch for the accuracy, reliability, and comprehensive nature of the information presented here regarding the Common Flat Bar Dimensions. My accumulated knowledge over the years underscores the importance of grasping how a flat bar’s size influences its potential applications.

Conclusion

Understanding flat bar sizes, industry standards, and flat bar variations is crucial for individuals and businesses in related sectors. Enhanced comprehension of these areas contributes to better decision-making, operational efficiency, and market competitiveness. As a staple in various industries, it highlights the significance of being in sync with such nuances.