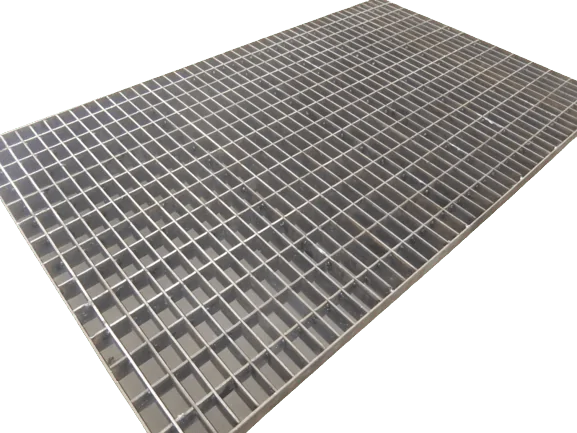

General Introduction To Press-locked Steel Grating: All You Need To Know

- Superior quality press-locked steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

Expanded Metal Wire Mesh

Expanded Metal Wire Mesh - Your Solution for Strong and Versatile Metal Mesh

What is Expanded Metal Wire Mesh?

Types of Expanded Wire Mesh

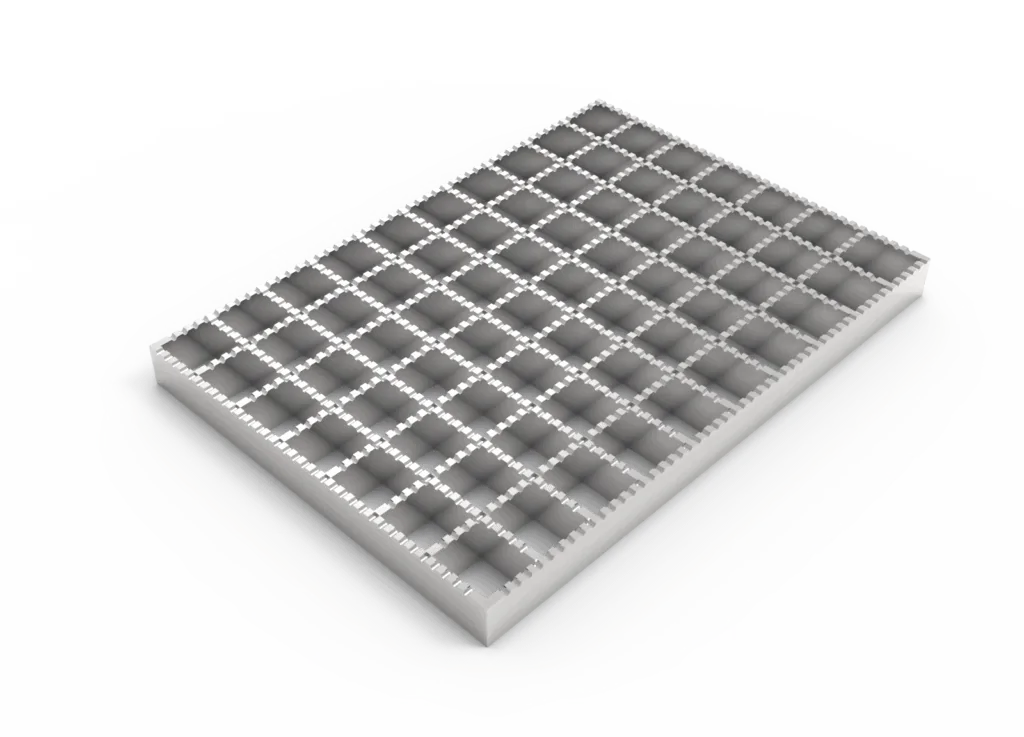

Standard Expanded Metal Wire Mesh

Standard expanded metal wire mesh is a versatile and widely used option for various applications. It features a diamond-shaped pattern with interconnected strands, resulting in a durable and robust mesh structure. This type of expanded metal wire mesh is known for its excellent strength-to-weight ratio, making it suitable for applications requiring high structural integrity.

Flattened Expanded Metal Wire Mesh

Flattened expanded metal wire mesh is created by passing the standard expanded metal through a rolling process, which flattens the diamond-shaped openings. This process not only provides a smooth and flat surface but also enhances the rigidity and strength of the mesh. The flattened design makes it an ideal choice for architectural applications, fencing, grating, and platforms where aesthetics and durability are crucial.

Micro Expanded Metal Wire Mesh

Micro expanded metal wire mesh is characterized by smaller diamond-shaped openings compared to standard expanded metal. It offers enhanced precision and finer details, making it suitable for specialized applications such as filtration, sieving, and fine mesh screens. The smaller openings allow for increased control over particle size, making it highly effective in separating and filtering materials.

Decorative Expanded Metal Wire Mesh

Decorative expanded metal wire mesh combines functionality with aesthetic appeal, making it an excellent choice for architectural and interior design applications. It features intricate patterns and designs that add visual interest to spaces while serving practical purposes such as partitions, cladding, facades, and decorative elements. This type of expanded metal wire mesh is available in a range of patterns, finishes, and customization options to meet specific design requirements.

Raised Expanded Metal Wire Mesh

Raised expanded metal wire mesh is produced by a process that raises the expanded metal strands, creating a three-dimensional effect. This type of mesh offers improved traction and grip, making it suitable for platforms, walkways, ramps, stair treads, and other applications that require slip resistance. The raised profile enhances load-bearing capabilities and provides additional strength and rigidity to the mesh.

Miniature Expanded Metal Wire Mesh

Miniature expanded metal wire mesh is characterized by its small diamond-shaped openings and thin strands. This type of mesh is commonly used in applications where lightweight, flexible, and delicate materials are required, such as filters, vents, battery electrodes, speaker grilles, and model-making. It offers excellent airflow, light transmission, and versatility in various intricate designs and shapes.

Security Expanded Metal Wire Mesh

Security expanded metal wire mesh is designed to provide maximum security and protection against intrusion while maintaining visibility and airflow. It features small diamond-shaped openings with closely spaced strands, making it difficult to penetrate or cut through. This type of mesh is commonly used in high-security areas, prisons, window grilles, fencing, and gates where safety is a top priority.

Expanded Wire Mesh Specifications

| Material options | Stainless steel, galvanized steel, aluminum |

|---|---|

| Thickness range | 0.5mm - 6mm |

| Opening size range | 3mm - 50mm |

The application of Expanded Wire Mesh

Expanded wire mesh is a versatile and widely used material that finds applications in various industries and sectors. Its unique properties and design make it suitable for a wide range of purposes. Here are some common applications of expanded wire mesh:

- Industrial and Manufacturing:

- Filtration: Expanded wire mesh is commonly used in filtration systems to separate solids from liquids or gases. It offers excellent strength, durability, and precise filtering capabilities.

- Screening and Sorting: It is utilized in industries such as mining, agriculture, and construction for screening and sorting materials based on size and quality.

- Reinforcement: Expanded wire mesh is employed in concrete reinforcement to improve structural integrity, prevent cracking, and enhance load-bearing capacity.

- Heat Dissipation: It is utilized in heat exchangers and air ventilation systems to facilitate efficient heat dissipation and airflow.

- Architecture and Construction:

- Facades and Cladding: Expanded wire mesh is utilized in building facades and cladding to enhance aesthetics, provide sunshade, and ensure proper ventilation.

- Interior Design: It is used for decorative purposes such as room dividers, decorative panels, and ceilings, adding a unique and modern touch to interior spaces.

- Safety and Security: Expanded wire mesh is employed for window and door security grilles, fencing, barriers, and guardrails to provide protection while maintaining visibility.

- Automotive and Transportation:

- Grilles and Vents: Expanded wire mesh is used in automotive applications for grilles, vents, and radiator covers, providing airflow while protecting against debris and insects.

- Cargo Containment: It is utilized in transportation vehicles to secure and contain cargo, preventing it from shifting during transit.

- Agriculture and Farming:

- Animal Enclosures: Expanded wire mesh is used for fencing, enclosures, and cages in livestock and poultry farming, ensuring animal safety and containment.

- Crop Protection: It is employed as a protective barrier to shield crops from pests, birds, and other animals while allowing sunlight, air, and water to reach the plants.

- Energy and Utilities:

- Battery Electrodes: Expanded wire mesh is used as electrodes in batteries, providing a high surface area for efficient energy transfer.

- Solar Panels: It is utilized as a support structure and protective layer in solar panels, ensuring durability and allowing for optimal sunlight exposure.

- Electronics and Appliances:

- Speaker Grilles: Expanded wire mesh is commonly used as speaker grilles in audio equipment, providing protection and allowing sound to pass through.

- Ventilation and Airflow: It is employed in electronic devices and appliances for ventilation and airflow management, preventing overheating.

FAQs for Expanded Wire Mesh

Expanded wire mesh is a versatile material made by cutting and stretching a sheet of metal, creating a pattern of interconnected diamond-shaped openings. It is known for its strength, durability, and flexibility, making it suitable for a wide range of applications.

Expanded wire mesh offers several advantages:

- Excellent strength-to-weight ratio: It provides high structural integrity while remaining lightweight.

- Enhanced visibility and airflow: The diamond-shaped openings allow for increased visibility and airflow, making it suitable for applications requiring ventilation or visibility.

- Versatility: Expanded wire mesh can be easily customized to meet specific design requirements and is available in various materials, sizes, and finishes.

- Durability: It is resistant to corrosion, impact, and wear, ensuring long-lasting performance in different environments.

- Cost-effective: Expanded wire mesh offers a

Expanded wire mesh has numerous applications across various industries:

- Architectural: Building facades, cladding, interior design elements, and safety grilles.

- Industrial: Filtration, screening, concrete reinforcement, and heat dissipation.

- Automotive: Grilles, vents, cargo containment, and vehicle accessories.

- Agriculture: Fencing, enclosures, crop protection, and animal cages.

- Electronics and Appliances: Speaker grilles, ventilation, and airflow management.

- Energy and Utilities: Battery electrodes, solar panel support, and protective layers.

Yes, expanded wire mesh can be customized to meet specific design and application requirements. It can be tailored in terms of material, opening size, strand thickness, sheet size, and finish. Customization options allow for precise filtration, aesthetic enhancements, and optimal performance in various industries and projects.

Expanded wire mesh can be installed using various methods such as welding, bolting, or clamping, depending on the specific application. It is important to follow the manufacturer’s guidelines and consult with professionals for proper installation. Maintenance typically involves periodic cleaning to remove debris and prevent corrosion. Regular inspections should be conducted to identify any damage or wear and ensure timely repairs or replacements.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397