Have you ever walked on a bridge, in a factory, or even in some urban spaces and noticed the robust metal grids underfoot? Those are steel gratings, a crucial yet often overlooked component of many infrastructures. But what’s the story behind their design? Why have they become so pivotal in modern construction?

Steel gratings have come a long way since their inception. From rudimentary designs of the past to intricate, technology-infused patterns of today, these grids are integral to both function and safety in numerous settings. Understanding the evolution of steel grating designs not only unveils a captivating history but also underscores their significance in our day-to-day lives.

As we delve into this topic, you’ll discover the remarkable journey of steel grating designs and their transformative role in shaping safe and efficient infrastructures around the world. Stick around; this evolution is more enthralling than you might think.

Early Origins of Steel Grating

Before the widespread adoption of steel, gratings were crafted using a variety of materials, each serving a distinct purpose based on the era and geography. The initial grating designs had a simple, functional purpose: providing a walkable surface that allowed for drainage or aeration.

Historical Context and Earliest Uses

In ancient civilizations, wood and stone were the primary materials used for grating-like structures. For instance, wooden grids were employed in agricultural settings for drainage or to separate grains. Stone gratings, on the other hand, found use in public baths and aqueducts in civilizations like the Romans. These early gratings, while rudimentary, underscore the age-old need for surfaces that could bear weight and allow the passage of water or air.

Before Steel: Primitive Designs

The primitive designs were primarily about functionality, with little emphasis on durability or aesthetics. Materials were chosen based on availability and ease of crafting. Bronze and iron were later incorporated, especially in settings requiring added strength or resistance to wear.

Advent of Steel in Grating Design

The shift from using varied materials to predominantly steel for gratings marked a significant turning point. Steel, with its superior properties, became a game-changer in grating design.

Why Steel?

The transition was fueled by the Industrial Revolution. With advancements in steel production techniques and its abundant availability, steel soon became the material of choice. Its consistent quality and the ability to produce in large quantities made it ideal for industrial and public infrastructures.

Benefits of Steel

- Durable, could withstand the test of time and harsh environmental conditions

- Unmatched load capacity, perfect for heavy-duty applications

- Resistant, could bear environmental factors like corrosion, especially when treated or coated

Types of Steel Grating Designs

As steel grating became more popular, various designs emerged to cater to specific needs and environments. Each design type offers unique features, ensuring optimal performance.

| Plain Bar Grating | This is the most common type of steel grating. Characterized by its simple design, it consists of parallel bearing bars that are held together by perpendicular cross bars. Due to its straightforward design and robust nature, it’s widely used in a variety of applications ranging from industrial floors to walkways. |

| Serrated Bar Grating | Ideal for environments where slip resistance is crucial, serrated bar gratings come with notched bearing bars. These notches provide added grip, making them perfect for oily or wet areas, such as industrial plants or outdoor settings. |

| Press-locked Grating | Crafted by hydraulically interlocking perpendicular bars, press-locked gratings provide a smooth surface. Their aesthetic appeal combined with strength makes them ideal for architectural applications, sidewalks, or sunshades. |

| Heavy-duty Grating | Designed specifically to withstand high loads, heavy-duty gratings are robust and durable. With thicker bars and increased spacing, they are typically used in areas with heavy machinery or vehicular traffic, such as industrial plants or roadways. |

Technological Advancements in Steel Grating Production

Over the years, the production of steel gratings has witnessed a remarkable transformation, thanks to technological advancements.

Manufacturing Techniques Through Time

Initially, manual methods dominated steel grating production. Welding, for example, was done by hand. However, as technology advanced, automated welding machines were introduced, ensuring uniformity and consistency. Modern hydraulic pressing techniques replaced traditional methods for creating press-locked gratings, enhancing precision and scalability.

The Tech Impact

The incorporation of technology in production has led to increased efficiency — more gratings produced in less time with reduced wastage. Precision has seen a marked improvement, with each grating adhering to stringent quality standards. Additionally, technology has allowed for greater customization, letting manufacturers cater to specific client requirements, from unique patterns to varying thicknesses.

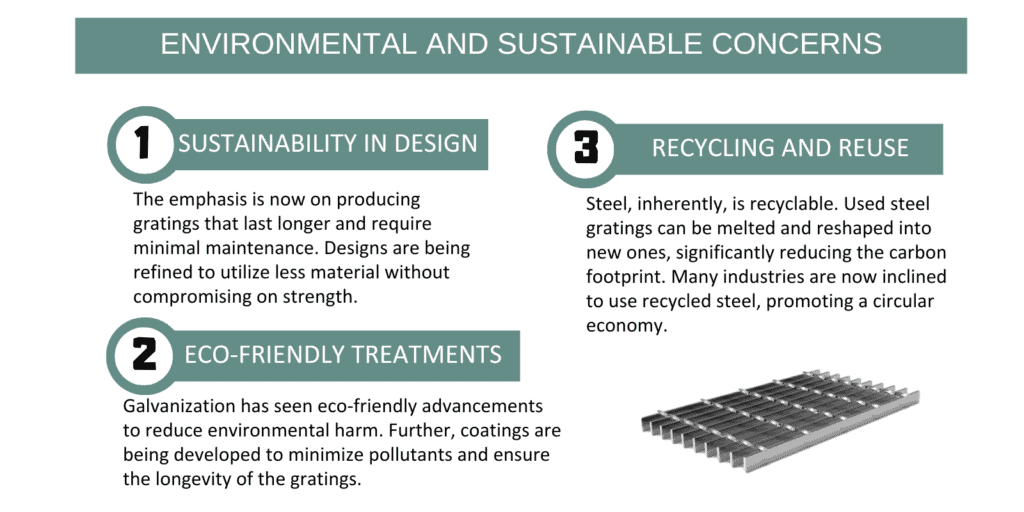

Environmental and Sustainable Concerns

With growing awareness about environmental degradation and sustainability, steel grating designs and production have evolved to address these issues.

Future Trends in Steel Grating Designs

The future holds exciting prospects for steel grating designs, influenced by technological advancements and changing architectural trends.

- Smart Grating: Integrating sensors into steel gratings could monitor wear, detect structural issues, and measure environmental conditions like temperature and moisture.

- Innovations in Material Science: Future gratings may use composite materials or advanced steel alloys for improved lightness, strength, and environmental resistance.

- Design and Architecture Synergy: Upcoming steel grating designs will focus on aesthetic appeal, blending with modern architecture and enhancing safety features.

Conclusion

The narrative of steel grating designs is a testament to human ingenuity and adaptability. From rudimentary grids of ancient times to potential smart gratings of the future, their evolution reflects our constant quest for betterment. As they continue to evolve, steel gratings promise to remain an integral part of our infrastructural fabric, meeting the ever-changing demands of society.