Introduction

Filtration and separation processes are critical in a variety of industries, from oil and gas to food and beverage production. To achieve optimal results, it’s important to constantly explore new techniques and materials that can improve efficiency and cost-effectiveness.

In this article, we’ve explored 3 unique uses of knitted wire mesh in such applications, including gas-liquid separation, particle filtration, and catalytic support. By leveraging the unique properties of this versatile material, you can enhance the efficiency and performance of your operations, leading to cost savings and improved product quality.

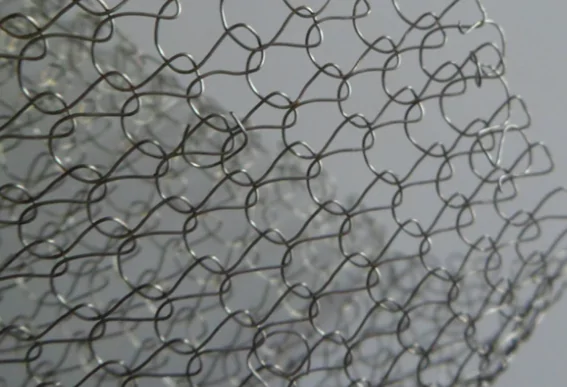

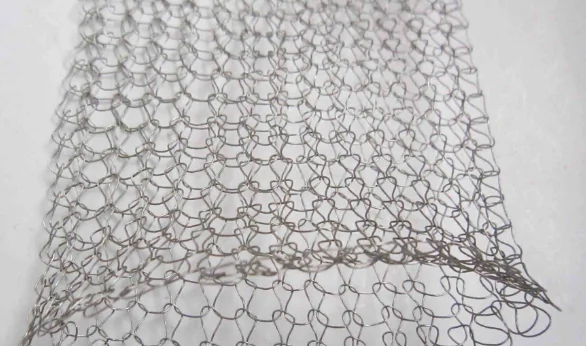

1. Definition of knitted wire mesh

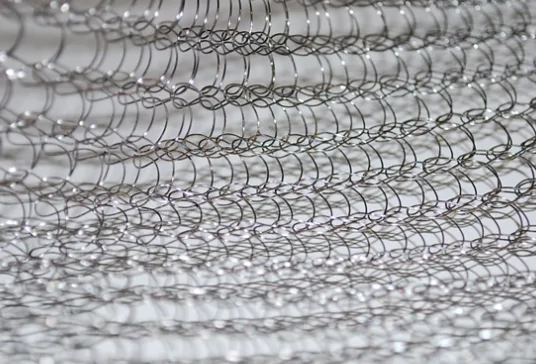

Knitted wire mesh is a durable and flexible material made from interlocking loops of metal wire. Unlike other types of wire mesh, knitted wire mesh is produced using a knitting process that creates a three-dimensional structure with high porosity and excellent resiliency.

This unique structure makes knitted wire mesh well-suited for applications in filtration and separation processes, where its high surface area and efficient flow characteristics can enhance the performance and longevity of various systems.

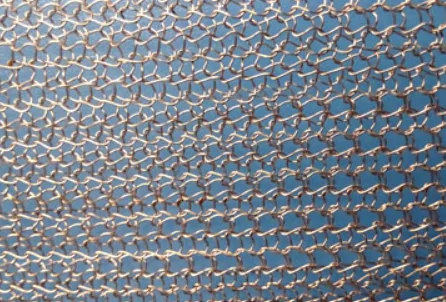

Knitted wire mesh is available in a variety of materials, including stainless steel, copper, and Inconel, among others, making it a versatile option for numerous industrial and commercial applications.

2. How it differs from other types of wire mesh

Knitted wire mesh differs from other types of wire mesh in several ways. Unlike woven wire mesh, which is created by interlocking individual wires in an over-under pattern, knitted wire mesh is produced using a unique knitting process that creates a three-dimensional structure with a higher degree of porosity and greater flexibility.

This structure allows for more efficient flow and improved filtration capabilities, making knitted wire mesh ideal for use in applications such as gas-liquid separation, particle filtration, and catalytic support.

Compared to expanded metal mesh, which is produced by stretching and punching a flat sheet of metal, knitted wire mesh is much more flexible and easier to manipulate into complex shapes. Knitted wire mesh also has a wider range of pore sizes and is available in a variety of materials, including stainless steel, copper, and Inconel, among others.

Knitted wire mesh offers a unique combination of durability, flexibility, and filtration capabilities that make it an attractive option for various industrial and commercial applications.

3. The versatility of its applications

Knitted wire mesh is a highly versatile material that finds applications in various industrial and commercial settings. Its unique structure and properties make it an excellent choice for applications that require efficient flow, high porosity, and filtration capabilities. Some common uses of knitted wire mesh include:

- Filtration and separation: Knitted wire mesh is widely used for gas-liquid separation, particle filtration, and catalyst support in various industries, including oil and gas, chemical processing, and wastewater treatment.

- Noise reduction: Knitted wire mesh can be used as a noise reduction material in automotive and industrial settings. Its porous structure helps to absorb sound waves and reduce noise levels.

- Heat transfer: Knitted wire mesh can be used as a heat transfer material in various industrial processes, such as drying, cooling, and heating. Its high surface area allows for the efficient transfer of heat between fluids.

- EMI shielding: Knitted wire mesh can be used as an electromagnetic interference (EMI) shielding material in electronics and telecommunications industries. Its conductive properties make it an effective shield against unwanted electromagnetic radiation.

- Seals and gaskets: Knitted wire mesh can be used as a sealing and gasket material in various applications, including automotive engines, HVAC systems, and industrial machinery. Its flexibility and resiliency allow it to conform to irregular surfaces and provide an effective seal.

The versatility of knitted wire mesh makes it a valuable material for a wide range of applications across various industries.

Uses in Industrial Sector

Knitted wire mesh is a versatile material that finds numerous applications in the industrial sector. Here are some of its common uses:

- Filtration and separation processes: Knitted wire mesh is an excellent filter medium for separating solids, liquids, and gases. Its three-dimensional structure allows for efficient flow and filtration, making it ideal for use in gas-liquid separation, particle filtration, and catalyst support.

- Protection against EMI/RFI interference: Knitted wire mesh can be used as a shielding material to protect against electromagnetic interference (EMI) and radio-frequency interference (RFI). Its conductive properties make it an effective barrier against unwanted electromagnetic radiation, making it useful in the electronics and telecommunications industries.

- Heat and flame protection: Knitted wire mesh can provide effective heat and flame protection in high-temperature environments, such as furnaces and industrial ovens. Its open structure allows for efficient heat transfer while providing a physical barrier against flames and hot gases.

- Gasketing and sealing: Knitted wire mesh can be used as a sealing and gasket material in various applications, including automotive engines, HVAC systems, and industrial machinery. Its flexibility and resiliency allow it to conform to irregular surfaces and provide an effective seal against air, liquids, and gases.

- Sound attenuation: Knitted wire mesh can be used as a noise reduction material in automotive and industrial settings. Its porous structure helps to absorb sound waves and reduce noise levels, making it useful in mufflers, silencers, and other noise-reduction applications.

Uses in Environmental Industry

Knitted wire mesh is a versatile material that can be used in various environmental applications. Here are some of its common uses in the environmental industry:

- Water and air purification: Knitted wire mesh is widely used for water and air purification. Its high porosity and efficient flow characteristics make it useful for removing contaminants from liquids and gases, including wastewater treatment, air pollution control, and chemical processing.

- Waste management: Knitted wire mesh can be used in waste management applications, such as landfill leachate treatment and sludge dewatering. Its filtration capabilities allow for the removal of solids and impurities from waste streams, helping to reduce the environmental impact of waste disposal.

- Landscaping: Knitted wire mesh can be used in landscaping applications, such as erosion control and slope stabilization. Its flexibility and durability make it an effective material for retaining soil and preventing erosion in steep or unstable terrain.

- Animal enclosures: Knitted wire mesh can be used in animal enclosures to provide a physical barrier while allowing for ventilation and visibility. Its strength and resilience make it ideal for use in aviaries, zoo exhibits, and other animal enclosures where safety and security are critical.

Uses in Artistry and Design

Knitted wire mesh is a versatile material that can be used in various artistry and design applications. Here are some of its common uses:

- Jewelry making: Knitted wire mesh can be used to create unique and intricate jewelry designs. Its flexibility and resiliency allow it to be shaped into various forms, while its durability ensures that the jewelry will last.

- Fashion designing: Knitted wire mesh can be used in fashion design to create stunning, one-of-a-kind pieces. Its unique texture and structure make it an attractive material for use in clothing, accessories, and footwear.

- Home décor: Knitted wire mesh can be used in home décor applications, such as lampshades, room dividers, and decorative screens. Its versatility and flexibility allow it to be shaped and molded to fit various design requirements.

- Sculpture: Knitted wire mesh can be used in sculpture to create dynamic and intricate forms. Its strength and flexibility allow for the creation of complex shapes and structures, making it an ideal material for sculptors and artists.

Knitted wire mesh’s unique properties make it a valuable material for various artistry and design applications across multiple industries. Its flexibility, durability, and unique texture make it a favorite among designers and artists who want to create distinctive and eye-catching designs.

4. Advantages of Knitted Wire Mesh

Knitted wire mesh offers several advantages over other materials, making it a popular choice for various industrial and commercial applications. Here are some of its key benefits:

- Durability: Knitted wire mesh is a durable material that can withstand high temperatures, corrosion, and wear and tear. Its interlocking loop structure provides strength and resilience, ensuring that it will last for extended periods.

- Flexibility: Knitted wire mesh is a flexible material that can be easily shaped and molded to fit various design requirements. Its pliability allows it to conform to irregular shapes and surfaces, making it an ideal material for use in complex structures.

- Customizability: Knitted wire mesh can be customized according to specific project needs. It comes in a variety of materials, such as stainless steel, copper, and Inconel, and pore sizes, allowing for customization based on factors like flow rate, filtration capacity, and desired level of conductivity.

- Cost-effectiveness: Knitted wire mesh is a cost-effective material that delivers maximum value for the invested amount. Its durability and long lifespan ensure that it requires minimal maintenance and replacement costs over time, making it a cost-efficient solution for various industrial and commercial applications.

Overall, the advantages of knitted wire mesh make it a popular choice for many applications. Its combination of durability, flexibility, customizability, and cost-effectiveness offers exceptional performance and quality, making it an attractive option for various industries from filtration and separation processes to art and design applications.

Conclusion

In conclusion, knitted wire mesh is a highly versatile material that offers numerous advantages in filtration and separation processes. Its unique three-dimensional structure and high porosity make it an excellent choice for gas-liquid separation, particle filtration, and catalytic support applications. By leveraging these benefits, businesses can improve the efficiency and performance of their operations, leading to cost savings and enhanced product quality. As such, knitted wire mesh is a valuable material worth considering for any application that requires efficient flow, filtration, shielding, or protection.