Introduction

Have you ever heard of hexagonal wire mesh? Maybe you’ve seen it in hardware stores or online, but you aren’t quite sure what it is or what it’s used for. This article will explain exactly what hexagonal wire mesh is, and how it is used in a variety of applications.

Know more about the features of hexagonal wire mesh including its material, surface treatment, aperture size, and length. Explore its benefits and different applications.

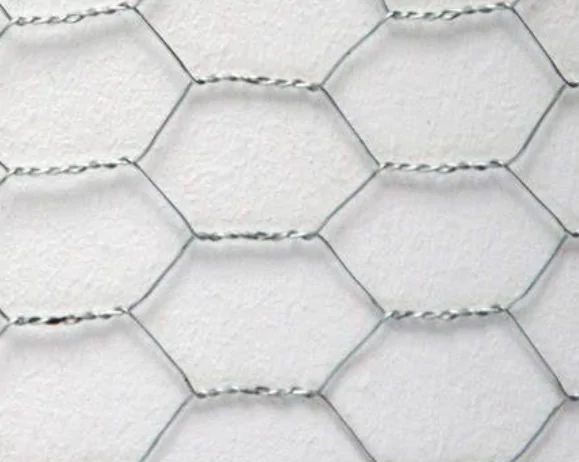

1. What is a hexagonal wire mesh

Hexagonal wire mesh, also known as chicken wire or poultry netting, is a type of wire mesh that is made by weaving wire into a hexagonal pattern. It is commonly used in a variety of applications such as poultry fencing, garden fencing, and as reinforcement for concrete.

Here are some features of hexagonal wire mesh:

Durability

Hexagonal wire mesh is made of high-quality galvanized steel wire or PVC-coated wire, making it resistant to corrosion and rust. This makes it a long-lasting option for fencing and other applications.

Flexibility

The hexagonal shape of the wire mesh makes it flexible and easy to shape into different forms. This makes it a versatile material that can be used for a variety of applications.

Lightweight

Hexagonal wire mesh is lightweight and easy to handle, making it easy to install and move around as needed.

Good visibility

The open design of the hexagonal wire mesh allows for good visibility, making it ideal for fencing in gardens or other areas where you want to be able to see through the fence.

Good ventilation

The open design of the hexagonal wire mesh also allows for good ventilation, which is important for applications such as poultry fencing where good airflow is necessary.

Cost-effective

Hexagonal wire mesh is relatively inexpensive compared to other types of fencing materials, making it a cost-effective option for many applications.

2. Different specifications of hexagonal wire mesh

Material

The material used to make hexagonal wire mesh can vary, but it is typically made from either galvanized steel wire or PVC-coated wire. Galvanized steel wire is a type of steel wire that has been coated with a layer of zinc to protect it from rust and corrosion.

A PVC-coated wire is made by coating the wire with a layer of polyvinyl chloride (PVC) to provide additional protection against corrosion and give it a longer lifespan. In addition to these materials, other types of wire such as stainless steel wire, aluminum wire, or brass wire can also be used to make hexagonal wire mesh depending on the specific application requirements.

Surface treatment

The surface treatment of a hexagonal wire mesh can vary depending on the material used and the specific application requirements. Here are some common surface treatments for hexagonal wire mesh:

- Galvanization

Galvanization is a process of coating the wire mesh with a layer of zinc to protect it from rust and corrosion. This is a common surface treatment for hexagonal wire mesh made from steel wire.

- PVC coating

PVC coating is a process of coating the wire mesh with a layer of polyvinyl chloride (PVC) to provide additional protection against corrosion and give it a longer lifespan. This is a common surface treatment for hexagonal wire mesh made from both steel and other types of wire.

- Powder coating

Powder coating is the process of applying dry powder paint to the wire mesh and then heating it to form a hard, durable surface. This is a common surface treatment for hexagonal wire mesh used in architectural or decorative applications.

- Painting

Painting is a simple surface treatment that can be used to provide some level of protection against rust and corrosion. However, it may not be as effective as other surface treatments and may need to be reapplied periodically.

The choice of surface treatment will depend on the specific requirements of the application, such as the environment in which the wire mesh will be used, the level of protection needed, and the desired appearance.

Aperture size

The aperture size of a hexagonal wire mesh can vary depending on the specific application requirements. The aperture size refers to the distance between two adjacent wire strands in the mesh, measured from the center of one wire strand to the center of the next wire strand.

The aperture size is usually specified in terms of the distance across the flat sides of the hexagon, also known as the “across flat” measurement. The most common aperture sizes for hexagonal wire mesh range from about 0.5 inches (13mm) to 2 inches (50mm), but other sizes are also available depending on the specific application.

The choice of aperture size will depend on the specific requirements of the application. For example, smaller aperture sizes are typically used for applications where smaller animals or birds need to be kept in or out, while larger aperture sizes may be used for applications where larger animals need to be kept out or where greater visibility and airflow are needed.

Length

The length of a hexagonal wire mesh can vary depending on the specific application requirements and the manufacturer. Typically, the length of a roll of hexagonal wire mesh ranges from 25 to 100 feet (7.6 to 30.5 meters) long, with widths ranging from 12 to 72 inches (30.5 to 183 cm).

However, it’s important to note that the length and width of the hexagonal wire mesh can be customized according to the specific needs of the application. Manufacturers can produce rolls of hexagonal wire mesh that are longer or shorter depending on the requirements of the customer.

In addition to rolls, hexagonal wire mesh can also be sold in panels, which can be prefabricated to the required dimensions for easier installation. The size and shape of the panels can also be customized according to the specific requirements of the application.

3. Benefits of hexagonal wire mesh

Stable

Hexagonal wire mesh is stable because of its unique hexagonal pattern, which provides stability and strength to the structure. The hexagonal pattern consists of a series of interconnected wire strands that are woven together to form a grid-like structure with six sides. This design distributes the weight and stresses evenly across the structure, providing a stable and durable framework that can withstand bending, twisting, and other types of deformation.

Easy installation

Hexagonal wire mesh is flexible and can be easily bent and shaped to fit the desired space. This makes it easy to install around corners and on uneven terrain. It is lightweight, which makes it easy to handle and install. It can be carried and installed by one or two people, which can reduce installation time and costs.

Hexagonal wire mesh is usually sold in rolls or panels, which can be easily connected or cut to fit the desired space. This modular design allows for easy installation without the need for special tools or equipment. This versatility means that it can be installed in many different settings and applications, making it a popular choice for many projects.

The easy installation of hexagonal wire mesh can benefit applications in several ways. It can reduce installation time and costs, make installation possible in difficult or remote locations, and allow for easy adjustments and modifications as needed.

Resistant to corrosion

Hexagonal wire mesh is often made from materials that are resistant to corrosion, such as galvanized steel, stainless steel, or PVC-coated wire. Here are some reasons why hexagonal wire mesh is resistant to corrosion:

Galvanized coating: Galvanized hexagonal wire mesh is coated with a layer of zinc, which provides a protective barrier against rust and corrosion.

Stainless steel: Stainless steel is naturally resistant to rust and corrosion, making it an ideal material for hexagonal wire mesh that will be used in harsh environments.

PVC coating: PVC-coated hexagonal wire mesh is coated with a layer of polyvinyl chloride (PVC), which provides a protective barrier against rust and corrosion while also providing additional resistance to abrasion and weathering.

The resistance to corrosion of hexagonal wire mesh can benefit applications in several ways. For example:

Durability: Hexagonal wire mesh that is resistant to corrosion can last longer and require less maintenance than mesh that is prone to rust and corrosion.

Aesthetics: Hexagonal wire mesh that is resistant to corrosion can maintain its appearance over time, which is important for applications where aesthetics are a concern.

Hygiene: Hexagonal wire mesh that is resistant to corrosion is easier to clean and sanitize, which is important for applications where hygiene is a concern, such as in food processing facilities.

4. Applications of hexagonal wire mesh

- Fencing

Hexagonal wire mesh is often used for fencing applications because it is strong enough to keep animals in or out, yet flexible enough to adapt to uneven terrain. It can also be easily cut and shaped to fit any space.

- Reinforcement

Hexagonal wire mesh is often used as reinforcement in concrete structures because it provides a stable framework for the concrete to adhere to. This can increase the strength and durability of the structure.

- Erosion control

Hexagonal wire mesh can be used for erosion control because it can be filled with soil or other materials to stabilize slopes and prevent soil erosion.

- Garden fencing

Hexagonal wire mesh can be used as garden fencing to protect plants from animals while still allowing sunlight, water, and air to reach the plants.

Conclusion

Hexagonal wire mesh is a versatile, economical, and reliable material for many applications. It is extremely strong, lightweight, and resistant to corrosion, making it an ideal choice for a variety of applications.

Its wide range of uses, including fencing, gabions, and soil reinforcement, makes it a popular choice for a variety of projects. With its strength, durability, and versatility, hexagonal wire mesh is a great choice for any project.